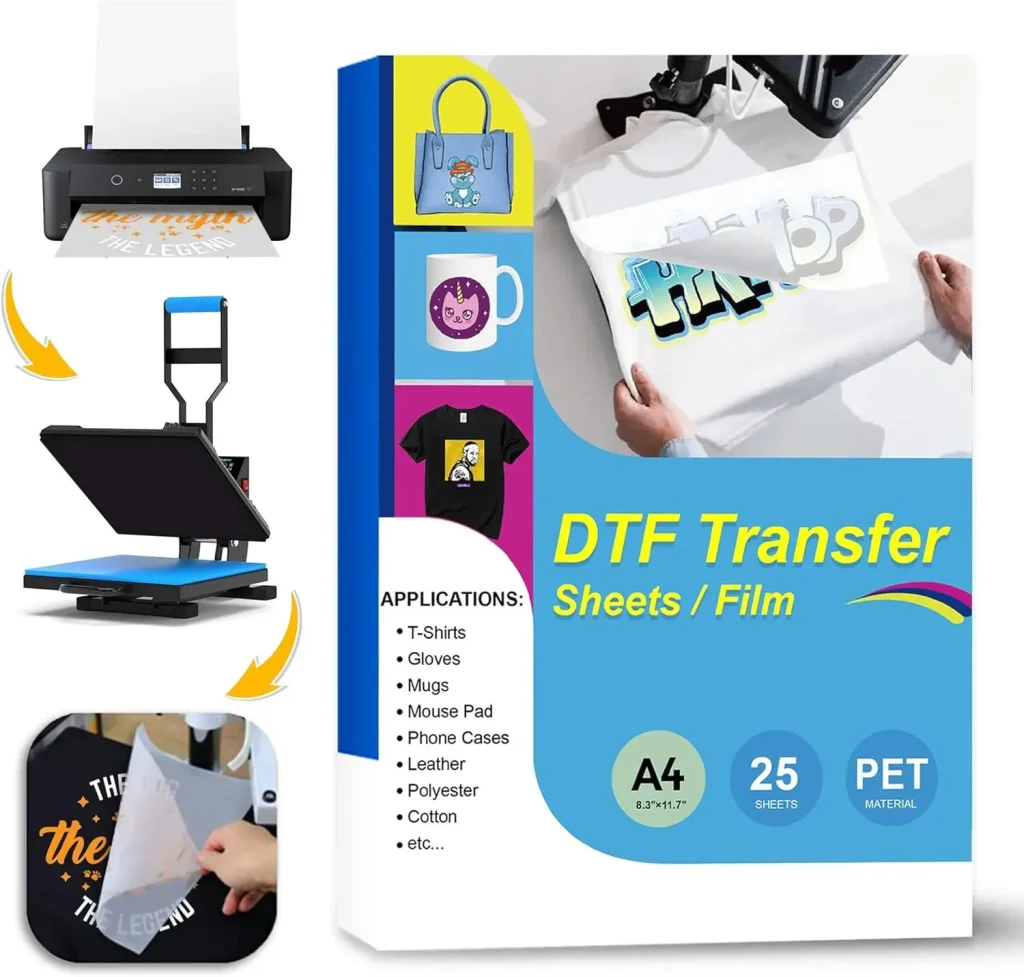

DTF transfer paper is an essential component in the burgeoning world of Direct-to-Film (DTF) printing, a technique that delivers unmatched quality and vibrancy for apparel decoration. Choosing the right DTF transfer paper can greatly influence the success of your printing projects, as it directly affects color fidelity and adhesion to fabric. In this guide, we will explore how to choose DTF transfer paper that meets your specific needs and enhances your designs. Additionally, we will cover tips for optimizing DTF printing quality and the best transfer paper for DTF that will help you achieve stunning results. By understanding the various transfer paper materials and their properties, you can take your printing capabilities to the next level and impress your customers with a professional finish.

When venturing into the world of Direct-to-Film printing, understanding the materials you work with is crucial for achieving exceptional results. Often referred to simply as DTF materials, these comprise various types of transfer paper that are paramount in the printing process. Selecting the right type of transfer film not only influences the quality of the final print but also affects how well the designs adhere to different fabric types. This overview will guide you in choosing the ideal film for your transfer needs, ensuring high-quality prints that stand out. With insightful DTF printing tips, you will learn how to maximize the potential of your chosen transfer solutions.

Choosing the Best Transfer Paper for DTF Printing

When it comes to DTF printing, the choice of transfer paper significantly affects the final product’s quality and vibrancy. To choose the best transfer paper for DTF applications, one must consider factors like material performance, adhesion, and printer compatibility. High-quality paper, such as those produced by reputable brands, typically excels in transferring detailed artwork onto fabrics seamlessly, resulting in stunning final products. It’s crucial to evaluate the specific requirements of your printer and the type of inks used, as this can greatly enhance your printing experience.

Moreover, taking time to read reviews and seek recommendations from experienced users can provide insight into which transfer papers yield the best results. Brands that receive positive feedback often highlight their transfer paper’s exceptional color reproduction and endurance under various washing conditions. Investing in the right transfer paper is essential for ensuring long-lasting results that meet both professional standards and customer expectations.

Key DTF Printing Tips for Optimal Results

To achieve the best results from DTF printing, incorporating several strategic tips into your workflow can be beneficial. One fundamental tip is to ensure that the printer settings are perfectly aligned with the chosen DTF transfer paper material. Various papers may require different ink saturation levels and print resolutions; thus, adjusting your printer settings can help you avoid potential transfer issues.

Another critical tip is to pay close attention to the heat transfer process. Proper temperature and pressure are essential in ensuring that the designs adhere firmly to the fabric without any damage. Utilizing a reliable heat press machine with precise temperature controls can prevent issues like uneven application or shifting of the design, ultimately enhancing the overall visual impact and longevity of the prints.

Understanding DTF Transfer Paper Materials

The material composition of DTF transfer paper is a key factor influencing print quality and overall performance. Most high-quality transfer papers are made from a PET (polyethylene terephthalate) base, which facilitates excellent heat transfer and color vibrancy. The adhesive mixture embedded within the paper further enhances print durability, ensuring that designs cling effectively to various fabric types without cracking or peeling.

When selecting DTF transfer paper, it’s important to look for those featuring superior adhesive technologies, as these significantly contribute to the longevity of the printed images. Understanding the nuances of transfer paper materials will help you choose the best options that align with your specific printing needs, ultimately leading to eye-catching results.

The Impact of Weight and Thickness on DTF Printing

Weight and thickness are important characteristics of DTF transfer paper that can influence its handling and the quality of the final prints. Lightweight transfer papers tend to be easier to manage during the heat transfer process, potentially making them ideal for intricate designs. However, one should consider the trade-off, as insufficient thickness can lead to poorer quality images that may not withstand normal wear and tear.

On the other hand, heavier transfer papers can often result in richer colors and improved longevity of prints, but they may require a more careful handling approach during application. Striking the right balance between weight and thickness based on your specific fabric types and printing techniques can significantly affect the outcome of your DTF projects.

The Importance of Manufacturer Reputation in DTF Printing

Manufacturer reputation plays a significant role in the world of DTF transfer paper. Opting for well-established brands can yield better results because these manufacturers have a history of producing reliable and high-performing products. Brands like Mediapak, Kornit, and Avery have built their names on quality, and their products often incorporate innovations that enhance printing performance.

Additionally, reputable manufacturers often provide detailed guidance on their products, including compatibility tips and best application practices. This kind of information can be invaluable for both seasoned professionals and newcomers, as it minimizes trial and error and maximizes efficiency in achieving desired results.

Conducting Tests for DTF Transfer Paper Selection

Before committing to a bulk purchase of DTF transfer paper, conducting preliminary tests with various options is highly recommended. Experimenting with different types of transfer papers on samples can help you evaluate their performance under different conditions, including variations in heat settings and fabric types. This hands-on approach allows for a real-world assessment of how well the transfer paper performs in relation to your specific printing needs.

Gathering feedback on your test prints can also provide insights that are crucial for making an informed decision. Observing how well the designs adhere, how vibrant the colors turn out, and the overall durability of the prints across different washing and wear conditions will help you identify which transfer paper best suits your needs and ensure quality output in your DTF printing projects.

Frequently Asked Questions

What should I consider when choosing DTF transfer paper for my projects?

When choosing DTF transfer paper, consider its material composition, compatibility with your printing equipment, weight and thickness, manufacturer reputation, and cost. High-quality PET-based papers with specialized adhesives ensure vibrant colors and durability.

What is the best transfer paper for DTF printing?

The best transfer paper for DTF printing typically features a PET base, high-quality adhesives, and is compatible with your specific printer and inks. Reputable brands like Mediapak and Kornit are recommended for reliable performance.

How does the weight and thickness of DTF transfer paper affect printing quality?

Weight and thickness are crucial for handling and print quality. Heavier DTF transfer papers generally provide better color vibrancy and durability but can be harder to manage, while lighter papers may sacrifice some image quality for ease of use.

What are some key DTF printing tips for using transfer paper effectively?

Key DTF printing tips include ensuring the right paper compatibility with your printer, testing different papers for optimal results, maintaining the correct heat and pressure during transfer, and choosing the right fabric for your designs.

How important is the manufacturer when selecting DTF transfer paper?

Choosing a reputable manufacturer is vital as established brands like Avery and Kornit offer consistent quality and performance. They can provide specialized options and customer support, enhancing your DTF printing outcomes.

Can I save money with cheaper DTF transfer paper options?

While cheaper DTF transfer paper can be tempting, investing in higher-quality options usually results in better durability, color quality, and overall satisfaction for your customers, making it a worthwhile investment.

| Key Factor | Description |

|---|---|

| Material Composition | DTF transfer paper typically uses a PET base for vibrant colors and effective heat transfer. |

| Compatibility with Equipment | Select transfer paper compatible with your printer model and inks for optimal results. |

| Weight and Thickness | Balance between lightweight (easier handling) and heavier (better quality) papers is crucial. |

| Manufacturer Reputation | Opt for reputable brands like Mediapak, Kornit, and Avery for reliable quality. |

| Cost Considerations | Investing in high-quality transfer paper can enhance print quality and customer satisfaction. |

| Conducting Tests and Gathering Feedback | Evaluate various papers through tests to find the best match for your printing needs. |

Summary

DTF transfer paper is a crucial element in achieving stunning print results in apparel printing. Choosing the right transfer paper involves weighing several important factors, such as material composition, compatibility with your printing equipment, and the desired weight and thickness of the paper. Opting for reputable brands can enhance the overall quality of your prints while keeping cost considerations in mind ensures budget-friendly yet effective choices. By carefully testing and selecting the right DTF transfer paper, you can significantly elevate your printing projects and satisfy your customer’s expectations, leading to lasting impressions in the competitive apparel market.