DTF transfers, or Direct-to-Film transfers, have revolutionized the garment printing industry by providing an innovative, efficient, and versatile method for creating high-quality prints on a wide range of fabrics. This advanced printing technique allows for vibrant, detailed designs to be applied, appealing to both professional printers and DIY enthusiasts alike. Understanding the DTF printing process is crucial for anyone looking to venture into custom apparel printing, as it unlocks new creative possibilities at lower costs compared to traditional methods. In addition, the eco-friendly alternatives available with DTF transfers align with the growing demand for sustainable practices within the fashion industry. By exploring DTF transfers, you can enhance your garment printing endeavors and stay competitive in a rapidly evolving market.

Exploring Direct-to-Film printing offers an exciting glimpse into modern garment decoration techniques that cater to the ever-evolving demands of the custom apparel sector. This method, known for its ability to produce exceptional prints on various materials, provides a compelling alternative to traditional direct-to-garment (DTG) and screen printing methods. The versatility of garment printing techniques such as DTF allows creators to experiment with intricate designs and vibrant colors, ensuring that their apparel stands out. As the trend for personalized clothing continues to rise, understanding the nuances of eco-friendly DTF transfers can lead to more sustainable business practices while meeting consumer expectations. Dive into the world of DTF printing and discover how this technology can enhance your creative projects and product offerings.

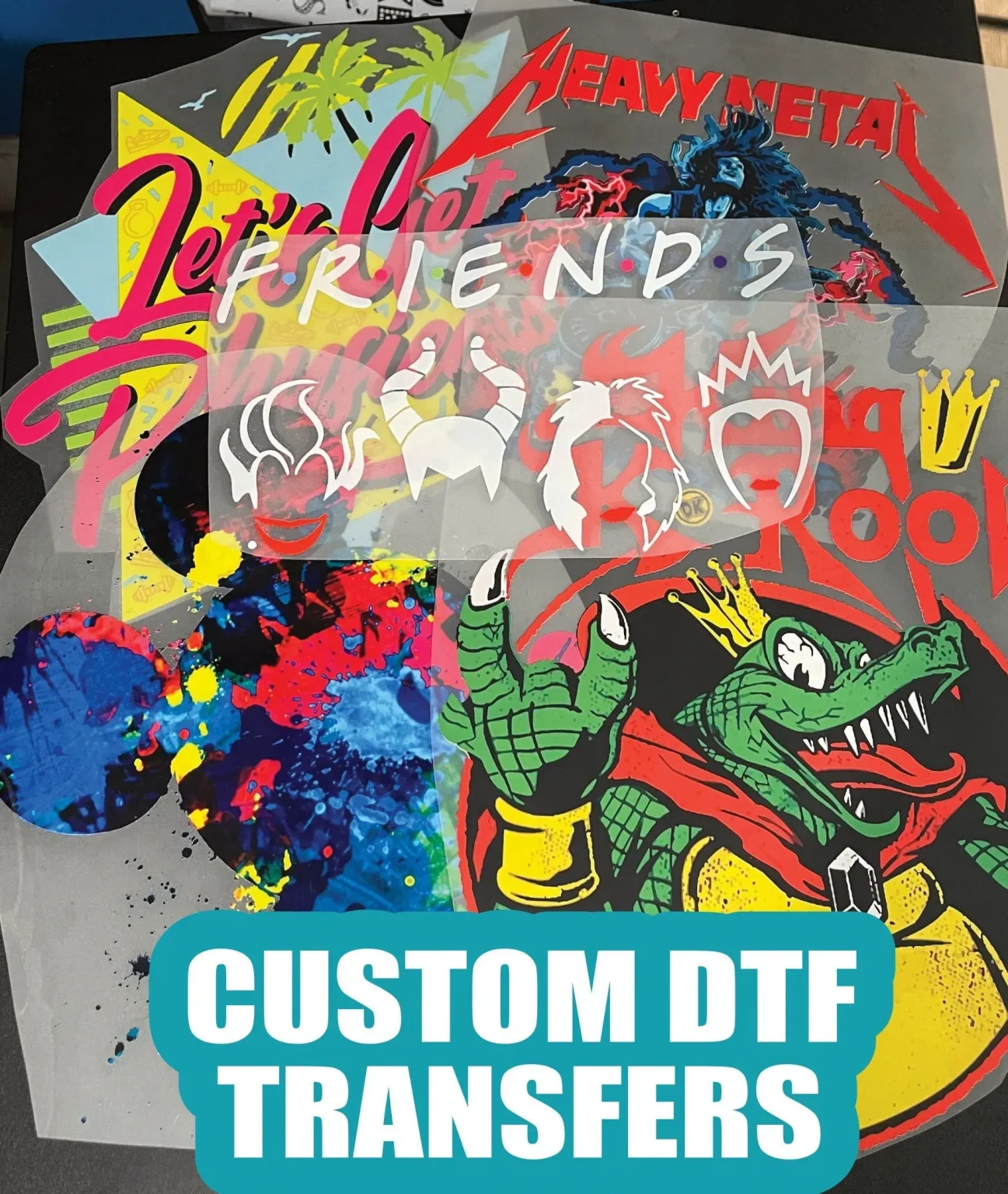

Understanding Direct-to-Film Printing: A Game Changer in Apparel

Direct-to-Film (DTF) printing has revolutionized the custom apparel industry, standing out for its innovative approach to garment decoration. Unlike traditional methods such as screen printing or direct-to-garment (DTG) printing, DTF uses a specialized film to transfer designs onto various fabric types. This process is characterized by its versatility, allowing for intricate designs with vibrant colors and the flexibility to print on different materials like cotton, polyester, and blends. DTF technology eliminates many of the limitations associated with conventional printing methods, making it a go-to option for businesses looking to offer unique and diverse products.

The efficiency of the DTF printing process cannot be overstated. With its ability to produce high-quality prints quickly, businesses can fulfill custom orders in a fraction of the time typically required for other printing methods. The reduced setup costs also make it an attractive solution for small business owners or hobbyists who wish to delve into custom apparel printing without heavy investment.

The Complete DTF Printing Process Explained

Understanding the DTF printing process is crucial for anyone looking to dive into this creative avenue. The process begins with design creation, where users utilize graphic design software to produce eye-catching visuals. Once the design is prepared, it is printed onto a specialized transfer film using a DTF printer equipped with high-quality inks for enhanced vibrancy. Following this, adhesive powder is applied to bind the printed ink to the film, which is then cured with heat to ensure durability.

Finally, the prepared transfer film is heat-pressed onto the garment, where the combination of heat and pressure allows the design to adhere permanently to the fabric. Upon cooling, the film is carefully peeled away, revealing the finished product. This step-by-step process highlights how DTF printing combines craftsmanship with modern technology, allowing for detailed and colorful designs that stand the test of time.

Advantages of Utilizing DTF Transfers for Custom Apparel

One of the most significant advantages of DTF transfers is their exceptional color versatility. Unlike many traditional printing methods that struggle with intricate designs involving multiple colors, DTF can produce high-resolution prints with a diverse color palette in a single application. This feature makes it an ideal choice for personalized items or promotional apparel, where vibrant designs are key to captivating customers.

Additionally, DTF transfers offer a cost-effective solution for small businesses and DIY creators alike. The low initial setup costs and minimal need for expensive equipment enable more entrepreneurs to enter the custom apparel market. Furthermore, DTF prints are known for their durability; when properly cured, these designs maintain their quality through multiple washes, ensuring that the final product meets customer expectations.

Key Developments and Market Trends in DTF Transfers

In recent years, advancements in DTF transfer technology have elevated its status in the printing industry. New printers and eco-friendly inks are continually being developed, enhancing print quality, efficiency, and sustainability. These innovations are not only improving production capabilities but also appealing to a more environmentally conscious consumer base that favors companies with responsible practices.

Market trends reveal a growing demand for custom apparel, primarily driven by individual consumer preferences for personalized clothing. Recognizing this trend, businesses are increasingly adopting DTF technology to stay competitive, offering unique products that cater to consumers’ desires for creativity and individuality in fashion. This shift underscores the importance of embracing DTF transfers within the garment printing landscape.

DTF Printing vs. Other Methods: A Comparative Analysis

When evaluating DTF printing against other popular methods, such as direct-to-garment (DTG) and screen printing, several distinct advantages emerge. DTF printing not only has lower initial setup costs compared to screen printing—where each color requires a unique screen—but also boasts faster production times. This speed is particularly advantageous for bulk orders or last-minute requests, making DTF a viable option for businesses with fluctuating demands.

Furthermore, DTF is celebrated for its ease of use and flexibility; it can accommodate a variety of fabric types, making it suitable for different projects ranging from sportswear to casual apparel. This adaptability allows businesses to expand their product offerings while maintaining high quality, a critical factor in retaining customer loyalty in the competitive custom printing market.

Sustainability in DTF Transfers: Eco-Friendly Practices

As sustainability continues to gain traction in the printing industry, companies specializing in DTF transfers are increasingly adopting eco-friendly practices. The use of environmentally safe inks and adhesives is on the rise, reducing the environmental impact of custom printing operations. These efforts are not only beneficial for the planet but also resonate with consumers who prioritize sustainable fashion.

Moreover, exploring the development of recyclable transfer films and minimizing waste in the DTF printing process reflects a commitment to improving sustainability across the industry. By focusing on eco-friendly DTF transfers, businesses can position themselves as leaders in the market, attracting environmentally conscious customers and differentiating their brand.

Frequently Asked Questions

What are the benefits of using DTF Transfers in garment printing?

DTF transfers provide numerous advantages for garment printing, including versatility with various fabric types, cost-effectiveness due to lower setup costs compared to screen printing, vibrant color reproduction for intricate designs, and durability that ensures quality even after multiple washes.

How does the DTF Printing Process work?

The DTF printing process involves several key steps: designing your artwork, printing it on DTF film, applying adhesive powder, curing the film, heat pressing the design onto the fabric, and finally peeling off the film. This method allows for high-quality, durable prints across a wide range of fabrics.

Can DTF Transfers be used on any type of fabric?

Yes, DTF transfers are compatible with a wide variety of fabrics, including cotton, polyester, and cotton-polyester blends, making them an excellent choice for custom apparel printing on diverse materials.

Are Eco-Friendly DTF Transfers available in the market?

Yes, the market is increasingly seeing eco-friendly DTF transfers as manufacturers adopt sustainable practices. This includes using eco-friendly inks and adhesives that minimize environmental impact while maintaining print quality.

What differentiates DTF Transfers from other printing techniques like DTG and screen printing?

DTF transfers differ from direct-to-garment (DTG) and screen printing primarily in their setup costs, print speed, and color capabilities. DTF offers lower initial costs, quicker turnarounds for complex designs, and the ability to print with multiple colors in a single process without requiring additional screens.

What should be considered to ensure high-quality DTF Transfers?

To ensure high-quality DTF transfers, it’s important to use high-quality films, inks, and adhesives, monitor the curing process closely, regularly maintain your DTF printer, and provide proper care instructions to customers to maintain print longevity.

| Section | Key Points |

|---|---|

| Introduction | DTF transfers enable high-quality prints on various fabrics, with vibrant designs and efficiency. |

| What Are DTF Transfers? | Involves printing on a special film for application to various fabrics, using a DTF printer, adhesive powder, and heat press. |

| The DTF Printing Process | Steps include design creation, printing on film, applying adhesive, curing, heat pressing, and peeling. |

| Advantages of DTF Transfers | DTF transfers are cost-effective, versatile, durable, and capable of vibrant multi-color prints. |

| Key Developments | Advancements in technology and increasing demand for custom apparel are shaping DTF transfer trends. |

| Best Practices | Utilize quality materials, ensure proper curing, maintain equipment, and provide washing instructions. |

| Environmental Considerations | Focus on exploring eco-friendly inks and processes to reduce carbon footprints in DTF printing. |

| Conclusion | DTF transfers are a key innovation in custom printing, providing quality and efficiency for modern businesses. |

Summary

DTF Transfers have revolutionized the custom printing landscape, offering unparalleled quality and versatility for garment printing. This innovative method not only caters to various fabric types but also ensures vibrant and detailed designs with impressive durability. Whether you are a hobbyist or a business owner, DTF Transfers provide an excellent opportunity to enhance your offerings and engage in the growing demand for personalized apparel. Embracing this technology can unlock new pathways for creativity and profitability in your printing endeavors.