DTF transfers, or Direct-to-Film transfers, are transforming the landscape of textile printing by providing an innovative and efficient way to apply intricate designs onto various materials. This cutting-edge method not only ensures vibrant colors and sharp details but also offers durability, making it an ideal choice for both hobbyists and small businesses alike. In the following sections, we will delve into the DTF transfer process, outlining every critical step to help you achieve professional-quality prints. Whether you’re a novice seeking a comprehensive DTF printing tutorial or an experienced printer looking to enhance your skills, you’ll find valuable insights that cater to your needs. Join us as we explore everything from design creation to the final heat transfer techniques that will bring your visions to life!

Direct-to-Film transfers, often referred to as DTF printing, represent a notable shift in printing technology, effectively bridging the gap between creativity and practicality. This technique utilizes a special film that captures designs with exceptional clarity and color vibrancy, making it suitable for a variety of applications, including apparel and promotional items. The DTF transfer process is user-friendly, allowing creators to produce high-quality results without extensive training. In this guide, we will cover multiple facets of DTF heat transfer, providing step-by-step instructions and tips for a seamless printing experience. Whether you’re interested in launching a new business or simply experimenting with new artistic expressions, DTF offers a versatile solution.

Understanding the DTF Printing Technique

DTF printing is an innovative method that transports designs onto textiles and other surfaces through a sophisticated direct-to-film process. This technique stands out due to its ease of use, allowing users to print high-resolution images that retain clarity and vibrancy. DTF transfers have gained traction among both amateur crafters and established businesses, thanks to their ability to produce intricate designs with minimal effort. The popularity of DTF printing lies not only in the visual impact of the prints but also in the versatility offered by the medium—it can be used on a variety of fabrics, from cotton to polyester.

One significant advantage of DTF printing is its compatibility with water-based inks, which are less harmful to the environment compared to solvent-based inks. This eco-friendliness is becoming increasingly important in today’s market, as more consumers seek sustainable products. Moreover, the ability to use DTF transfers on dark fabrics without the need for a white base layer is a game changer, allowing for richer, more vibrant designs that were previously challenging to achieve with other printing methods.

Frequently Asked Questions

What is the DTF transfer process and how does it work?

The DTF transfer process involves creating a design using graphic design software, printing it onto a special transfer film with water-based inks, applying a hot-melt adhesive powder, curing the film to bond the inks, and finally heat transferring the design onto fabric using a heat press. This method allows for vibrant and durable prints.

How can I get started with DTF printing?

To get started with DTF printing, you’ll need a DTF printer, transfer film, hot-melt adhesive powder, and a heat press. Begin by designing your artwork in high resolution (300 DPI or more) in a program like Adobe Illustrator. Print your design onto the transfer film, apply the adhesive powder, cure the film, and heat press it onto your chosen fabric for best results.

What are the benefits of using DTF transfers?

DTF transfers offer several benefits, including vibrant color reproduction, flexibility on various fabric types, and durability of prints. Unlike traditional methods like screen printing, DTF printing is cost-effective for small runs and can produce intricate designs with fine details, making it ideal for both businesses and hobbyists.

Is there a specific DTF printing tutorial for beginners?

Yes! The DTF printing tutorial provided in our guide covers the entire DTF transfer process step-by-step, from design creation to heat transfer application. It includes tips for selecting the right materials and settings to ensure successful prints, making it a valuable resource for beginners.

What common mistakes should I avoid during the DTF transfer process?

Common mistakes to avoid in the DTF transfer process include using low-resolution designs, not applying the adhesive powder evenly, and incorrect curing temperatures. Additionally, ensure you properly align your transfer during heat pressing and allow the fabric to cool slightly before peeling the film to prevent damaging your print.

What current trends are shaping the DTF printing industry?

Current trends in DTF printing include a focus on sustainability with eco-friendly inks and materials, along with advancements in printing equipment that offer faster speeds and higher quality outputs. Keeping up with these trends can enhance your DTF transfer results and attract eco-conscious customers.

| Step | Description | Tips |

|---|---|---|

| 1. Design Creation | Creating a design using software like Adobe Illustrator. | Use high resolution (300 DPI) and RGB color profiles. |

| 2. Film Preparation | Print the design on special DTF transfer film. | Ensure printer settings are correct for the film. |

| 3. Powder Application | Apply hot-melt adhesive powder to printed film. | Shake off excess powder to avoid mess. |

| 4. Curing the Transfer | Cure the film using heat to bond the ink and film. | Set temperature to 120-150°C for 1-2 minutes. |

| 5. Heat Transfer to Fabric | Use heat press to apply the transfer to fabric. | Press at 325°F for 10-15 seconds. |

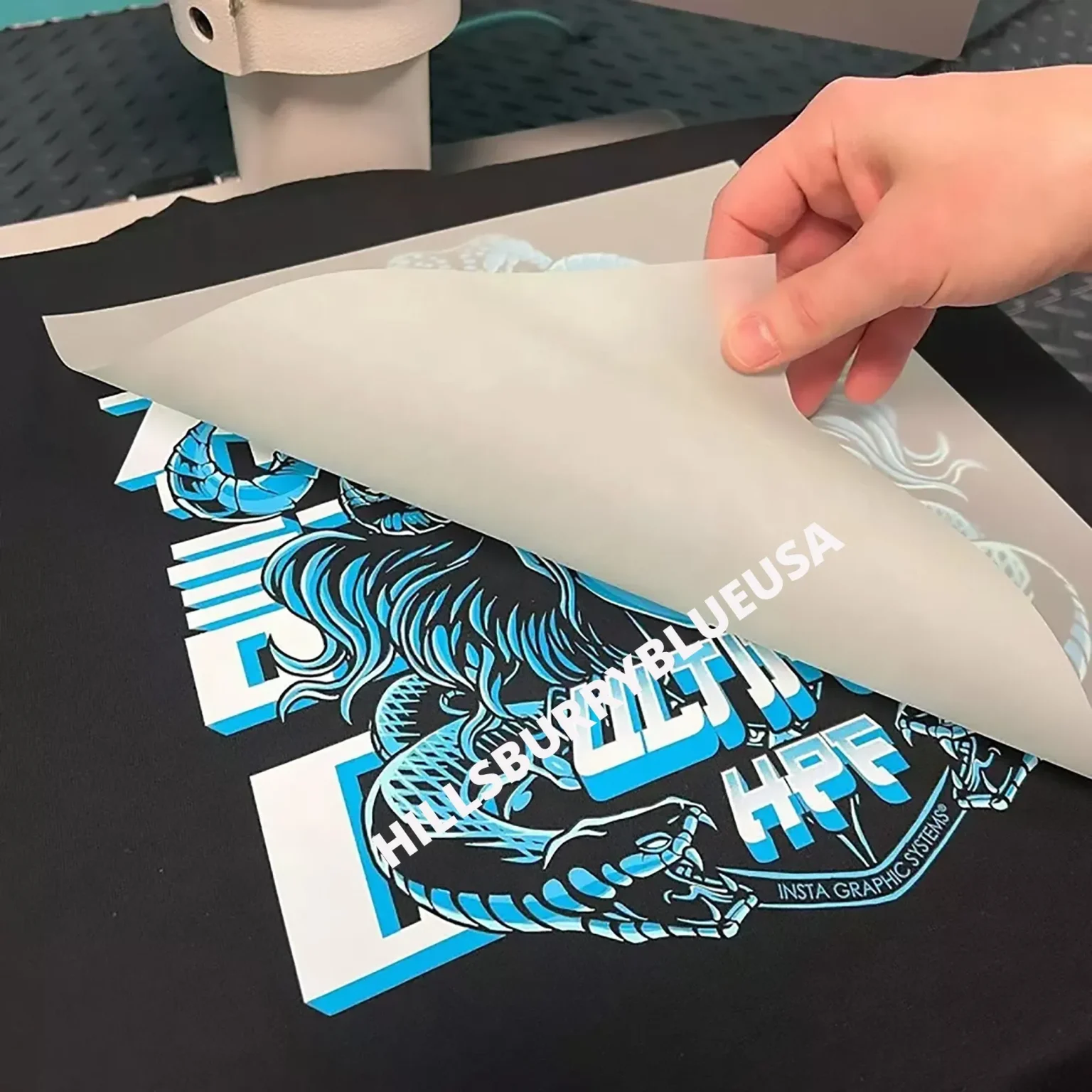

| 6. Peeling the Film | Peel away the film to reveal the design on fabric. | Allow cooling before peeling for better adhesion. |

Summary

DTF Transfers are a modern and efficient method for printing designs onto textiles and other surfaces. This tutorial details the entire process from creating stunning designs to applying them on fabric, ensuring a high-quality, professional finish. By integrating eco-friendly practices and utilizing advanced printing technologies, DTF transfers not only offer vibrant and intricate prints but also cater to contemporary consumer demands. Mastering DTF transfers opens up new creative and commercial opportunities, making it an essential skill for anyone in the printing and textile industry.