In the fast-evolving textile printing landscape, the **DTF Gangsheet Builder** has emerged as a crucial tool for designers seeking to enhance the quality and efficiency of their prints. This innovative application enables users to optimize gangsheet layouts for DTF (Direct to Film) printing, leading to more vibrant results and less waste. By implementing effective DTF printing techniques and following key textile design tips, you can ensure that your creations leap off the fabric with stunning clarity. Whether you’re a beginner or a seasoned pro, mastering the DTF Gangsheet Builder can revolutionize your workflow, showcasing your unique designs while maximising resources. Join us as we explore the best practices for utilizing this powerful tool to elevate your textile designs to new heights.

Navigating the realm of textile creation, the Direct to Film (DTF) Gangsheet Builder stands out as an essential component in modern printmaking. This advanced software assists in arranging graphics onto a single film sheet for efficient transfer onto fabric, making it a game-changer for apparel printing. Mastering the intricacies of gangsheet optimization, selecting the right transfer materials, and testing preliminary prints are all pivotal in achieving ideal results. The ability to effectively utilize this tool can significantly enhance your design game, ensuring that your prints not only capture attention but also maintain durability. Delve into our guide for insightful tips on maximizing the potential of the DTF Gangsheet Builder in your textile projects.

Understanding DTF Printing Techniques for Superior Textile Design

DTF printing techniques have revolutionized the textile industry by offering vibrant color options and high durability. By employing a specialized process where designs are printed onto a transfer film, it allows for easy application on various fabrics, from cotton to polyester blends. This method not only enhances design versatility but also ensures that prints can withstand multiple wash cycles without fading. Understanding the integral steps of DTF printing—from ink application to heat pressing—is key to mastering the craft of textile design.

Moreover, techniques like color calibration and material selection for inks significantly elevate the quality of your fabric prints. For instance, utilizing high-quality DTF inks can greatly enhance color saturation and reliability, allowing designers to achieve their desired aesthetic. Incorporating these DTF printing techniques into your workflow means you can cater to a wider range of textile products, from fashion apparel to custom merchandise.

Textile Design Tips That Maximize Your Prints

When it comes to textile design, there are several key tips that can help improve the overall quality and aesthetic appeal of your prints. Firstly, focusing on simplicity in design can often yield better results, especially when using the DTF Gangsheet Builder. Complex artwork may look good in a digital format but can get lost in translation during the printing process. Thus, incorporating bold colors and clear graphics can ensure that your designs translate seamlessly from screen to fabric.

Additionally, considering the scale of your designs is crucial. Large designs can dominate a smaller garment and look overwhelming, while tiny intricate designs might not be visible on larger pieces. Therefore, experimenting with scale and positioning when preparing your designs can greatly influence the final outcome. Make use of mockups to visualize how your designs will look on actual products before printing.

Maximizing Efficiency: How to Optimize Gangsheet Layout

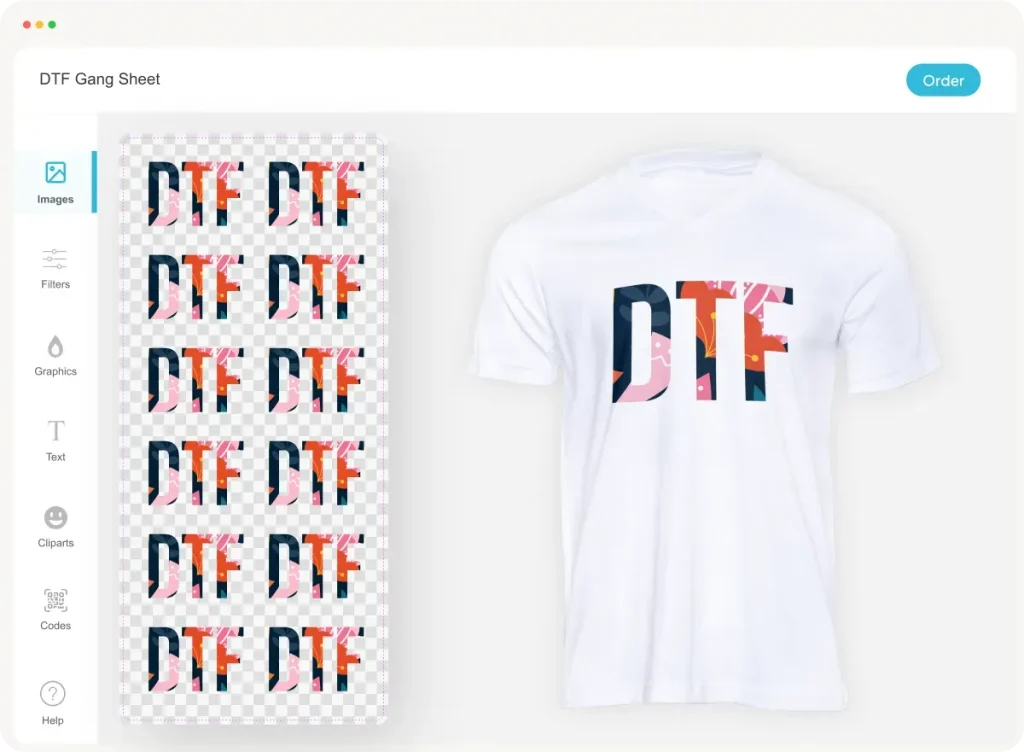

Optimizing the gangsheet layout is essential for efficiency in DTF printing. This process involves arranging your designs on the transfer film in a manner that minimizes waste and maximizes the use of film space. A well-thought-out layout not only saves materials but also contributes to a more organized workflow, allowing for quicker production times. You can use design software tools that allow you to visualize and adjust the placement before printing, ensuring that your layouts are cost-effective.

Furthermore, it’s important to account for spacing between designs. Adequate margins prevent overlapping during the printing process, which could compromise the quality of individual prints. A balanced approach to layout design—considering design sizes, orientations, and distances—plays a vital role in achieving a professional and polished final product.

Crucial Factors for Transfer Film Selection

Selecting the right transfer film is crucial in DTF printing as it can directly affect the print quality and durability of your textiles. The material of the transfer film influences how well the ink adheres and can impact the finished feel of the fabric. Different finishes, such as glossy or matte, offer diverse aesthetics that can complement different design styles. Therefore, understanding the characteristics of various types of films will by and large enhance the visual outcome of your prints.

For example, a glossy finish may provide a vibrant look ideal for bold, colorful designs, while matte may be better suited for more subdued or vintage styles. Additionally, ensuring that the transfer film is compatible with both your printer and the inks used is fundamental to avoiding quality issues during application. Always perform test prints on sample materials to evaluate how the chosen film performs during the transfer process.

Adjusting Printer Settings for Optimal Results

Adjusting your printer settings is integral to achieving stunning prints when utilizing the DTF Gangsheet Builder. Many printers offer customizable settings that can greatly influence the output quality, such as saturation levels, speed, and temperature. It’s pivotal to tailor these settings according to the specific materials and designs you’re working with to maximize print clarity and adherence. Recommended practices include starting with standard settings and then fine-tuning based on the color and fabric types.

Moreover, maintaining your printer is just as important as adjusting the settings. Regular cleaning of printers and nozzles prevents clogs and ensures consistent ink flow, leading to better print quality. Keeping track of ink levels will also prevent any interruptions in your projects, allowing for seamless print runs. Having a solid grasp of how printer adjustments affect the overall output empowers you to create exceptional textile designs.

Importance of Test Prints and Iteration in DTF Fabric Printing

Conducting test prints is a vital step in the DTF printing process. This practice of creating sample prints allows designers to assess how their designs will actually appear on fabric, which is essential for identifying potential issues before the final production run. Being able to spot discrepancies in color, alignment, or detail on test prints helps guide adjustments, ensuring the end products meet high standards of quality and precision.

Additionally, the opportunity for iteration based on test prints encourages a cycle of improvement. Gathering feedback from peers or clients on test prints can reveal insights that lead to substantial enhancements in your designs. Adopting a mindset geared toward experimentation and iteration results in continuous growth and superior output in textile design.

Frequently Asked Questions

What is the DTF Gangsheet Builder and how does it relate to DTF printing techniques?

The DTF Gangsheet Builder is a tool designed specifically for creating optimized layouts for Direct to Film (DTF) printing. It helps users maximize the efficiency of their prints by allowing them to group multiple designs on one sheet, thus reducing waste and enhancing production time. Mastering this tool is essential for effectively utilizing DTF printing techniques and achieving high-quality textile designs.

How can I optimize gangsheet layout using the DTF Gangsheet Builder?

To optimize gangsheet layout with the DTF Gangsheet Builder, start by preparing your artwork ensuring high resolution and proper color settings. Then, arrange designs closely without overlap to minimize waste. Utilize automated tools provided by the software for layout adjustments, prioritizing designs based on demand and print requirements for the best results.

What should I consider when selecting transfer film for DTF printing with the Gangsheet Builder?

When selecting transfer film for DTF printing using the Gangsheet Builder, consider the desired finish (glossy or matte), compatibility with your printer and inks, and the film’s durability. Choosing the right transfer film is crucial as it affects the look and longevity of your printed designs, thereby impacting quality in your textile prints.

What are some textile design tips for using the DTF Gangsheet Builder?

Some textile design tips for using the DTF Gangsheet Builder include ensuring high-resolution artwork for clarity, using a transparent background for better adhesion, and sticking to CMYK color mode for accurate color reproduction. Additionally, testing your designs through smaller prints before a full production run can help you make necessary adjustments.

Why are test prints important in the DTF printing process with the Gangsheet Builder?

Test prints are vital in the DTF printing process using the Gangsheet Builder as they allow you to assess how designs transfer onto fabric. By evaluating test prints, you can identify discrepancies with your original artwork, receive valuable feedback, and make adjustments, ensuring high-quality results in your final prints.

How can I adjust printer settings for optimal DTF printing results?

To achieve optimal DTF printing results with the DTF Gangsheet Builder, customize your printer settings to match your materials. Adjust saturation, speed, and temperature to enhance print quality. Regular maintenance, including cleaning printer heads and monitoring ink levels, is also essential for maintaining top performance and consistency in your prints.

| Key Points | Description |

|---|---|

| Understand Your Artwork Requirements | Prepare high-resolution images (300 DPI or higher) and ensure proper color calibration. |

| Optimize Gangsheet Layout | Group designs closely to minimize waste and maximize efficiency. |

| Choose the Right Transfer Film | Select an appropriate film type based on the desired finish and compatibility. |

| Adjust Printer Settings | Customize settings for saturation, speed, and temperature to improve print quality. |

| Test Prints and Iteration | Conduct test prints to gather feedback and make necessary adjustments. |

Summary

The DTF Gangsheet Builder is an innovative tool that can dramatically enhance your textile design process. By focusing on five critical areas—artwork preparation, gangsheet layout optimization, transfer film selection, printer settings adjustment, and thorough testing—you can ensure the quality and vibrancy of your prints. Implementing these best practices not only streamlines your workflow but also amplifies the creativity and craftsmanship that goes into each project. As you master the DTF Gangsheet Builder, prepare to transform your designs into unique textile prints that resonate with clients and customers alike.