DTF Gangsheet Builder Efficiency is essential for any print shop aiming to maximize their output and quality. By streamlining your processes, you can eliminate unnecessary waste while producing high-quality prints that satisfy customer expectations. This not only involves optimizing layout designs and using high-quality images but also ensuring proper printer calibration and integrating effective pre-treatment solutions for DTF printing. Implementing these DTF printing tips can significantly reduce costs and increase productivity, making your workflow more efficient. Join us as we explore five crucial strategies that will enhance your DTF printing process and propel your business to new heights.

When we talk about enhancing the performance of your DTF print operations, employing a well-thought-out Gangsheet Builder becomes key to achieving efficiency. Maximizing productivity in this context involves effectively managing your design layouts, utilizing superior graphics, and ensuring your printing equipment is meticulously calibrated. Moreover, effective pre-treatment techniques play a significant role in achieving the desired print quality, thus optimizing your overall DTF process. By focusing on these aspects, you not only enhance your workflow but also enrich the quality of the end products delivered to your clients.

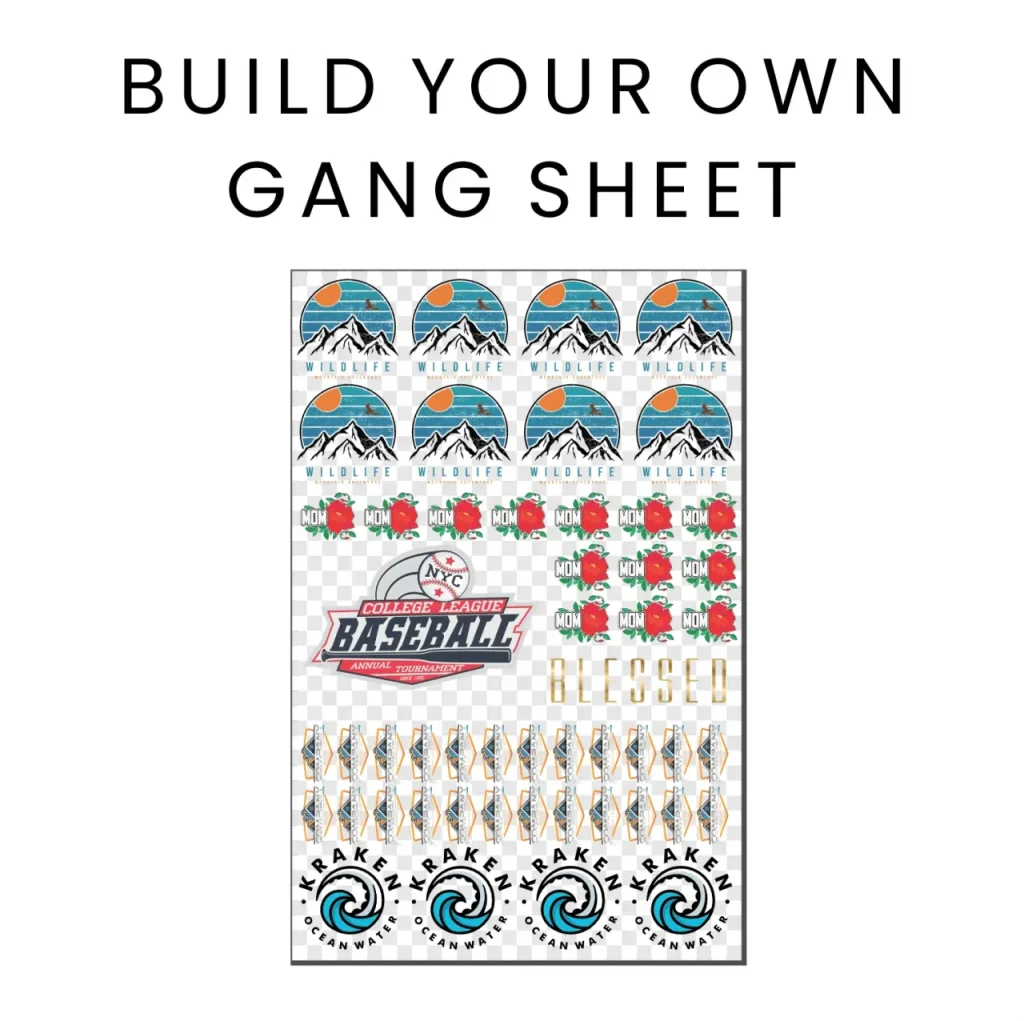

Maximize Efficiency with DTF Gangsheet Builder Techniques

To maximize efficiency with your DTF Gangsheet Builder, developing effective techniques is essential. Utilize software tools designed specifically for DTF printing, which can help you arrange graphics in a way that reduces waste. By aligning designs closely and selecting optimal layouts, you can ensure that you’re getting the most out of each piece of film. These advanced tools can also suggest the best possible arrangements based on your specified dimensions, promoting resource savings without compromising on print quality.

Moreover, consider investing in an intuitive interface that allows for drag-and-drop design features and adjustable grid spacing. Using such tools, you can optimize your layout in real-time, making quick modifications as needed. This agility not only enhances efficiency but also allows for creative freedom, enabling you to explore unique designs without the fear of excess waste.

Frequently Asked Questions

How can I optimize DTF Gangsheet Builder efficiency through layout design?

To optimize DTF Gangsheet Builder efficiency, arrange your designs to maximize space usage. Utilize digital templates and design clustering to minimize film waste and streamline the printing process.

What is the significance of using high-quality images for DTF printing?

Using high-quality images is crucial for DTF printing as it ensures clarity and detail in the final prints. Aim for images with at least 300 DPI and consider formats like PNG or TIFF to avoid compression artifacts.

How often should I perform printer calibration for DTF printing efficiency?

Regular printer calibration is essential for DTF printing efficiency. Schedule maintenance checks following manufacturer guidelines to maintain color accuracy and improve ink distribution, leading to fewer errors in prints.

What benefits do pre-treatment solutions provide for DTF printing?

Pre-treatment solutions enhance ink adhesion to fabrics, improving print vibrancy and quality. They also reduce ink consumption, leading to cost savings and more efficient printing operations.

What are some effective strategies to streamline DTF printing workflow processes?

To streamline your DTF printing workflow, create process maps to identify bottlenecks and implement automation tools. This can result in faster turnaround times and better productivity.

How can I ensure my DTF Gangsheet Builder is set up for high productivity?

Ensure high productivity in your DTF Gangsheet Builder by optimizing layout designs, using high-quality images, maintaining printer calibration, investing in effective pre-treatment solutions, and analyzing your workflow for efficiencies.

| Tip | Description | Key Strategies |

|---|---|---|

| 1. Optimize Layout Design | Maximizing design arrangement to minimize material waste. | – Use digital templates for specific machine sizes. – Cluster similar designs to speed up printing. |

| 2. Use High-Quality Images | Ensuring all images are high resolution to avoid print defects. | – Utilize images with at least 300 DPI. – Prefer formats like PNG or TIFF for quality. |

| 3. Calibrate Your Printer Regularly | Maintaining color accuracy and ink distribution for better performance. | – Schedule maintenance for your printer regularly. – Follow manufacturer guidelines for calibration. |

| 4. Invest in Pre-Treatment Solutions | Enhancing ink adhesion and reducing ink usage for cost efficiency. | – Good pre-treatment enhances print vibrancy. – Reduces ink consumption for lower costs. |

| 5. Streamline Workflow Processes | Identifying and eliminating bottlenecks for improved productivity. | – Create a workflow diagram to spot inefficiencies. – Use software tools to automate repetitive tasks. |

Summary

DTF Gangsheet Builder Efficiency is essential for optimizing your printing operation. By focusing on design layout, image quality, regular printer maintenance, pre-treatment investment, and streamlined workflows, businesses can see marked improvements in both speed and quality of output. Implementing these strategies ensures you are making the most of your resources, enhances customer satisfaction, and fosters profitability. Embracing these five critical tips will undoubtedly set the foundation for a successful DTF printing venture.