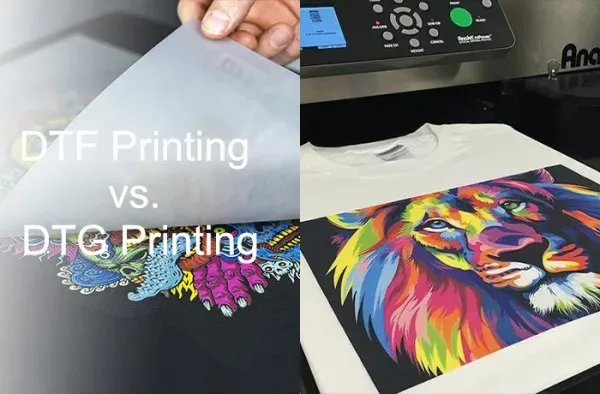

When comparing DTF vs DTG printing, business owners discover distinct techniques that cater to various needs in the textile industry. DTF printing advantages include versatility, allowing it to work seamlessly on diverse fabric types, while DTG excels in delivering high-quality print results, especially on cotton. As businesses seek the best printing method for business, evaluating cost-effective printing solutions like DTF can lead to better profit margins for smaller orders. In contrast, those prioritizing stunning visuals will find that DTG print quality surpasses expectations. Ultimately, understanding these fabric printing techniques ensures a well-informed decision that aligns with both customer demands and budget constraints.

In the realm of fabric decoration, the choice of printing process can significantly influence a business’s offerings and appeal. When discussing DTF and DTG methods, one is essentially considering options between direct-to-film and direct-to-garment techniques that differ in application and output. DTF, recognized for its adaptability across various materials, provides an economical solution, while DTG, known for its exceptional detail and vibrancy, shines in showcasing intricate designs. As your business explores viable printing options, it’s essential to weigh the benefits of each approach comprehensively. This foundational understanding will empower your brand to make astute printing choices that resonate with your market.

What Are the Key Differences Between DTF and DTG Printing?

DTF (Direct to Film) and DTG (Direct to Garment) printing are two revolutionary methods that have transformed the textile printing landscape. While both techniques aim to produce high-quality prints on fabrics, their processes and outcomes differ significantly. DTF printing involves printing designs onto a film, which is then transferred onto the fabric using heat and pressure. This allows for vibrant colors and intricate details on various types of fabric, making it especially effective for polyester blends. Meanwhile, DTG printing utilizes advanced inkjet technology to print directly onto garments, primarily cotton, resulting in stunningly detailed and photorealistic images that really pop on lighter fabrics.

The choice between DTF and DTG should be based on your business requirements and target market. If you cater primarily to an audience demanding colorful designs on a wide range of fabrics, DTF might be the way to go. On the other hand, if your clientele seeks top-notch quality and fine detail, especially on cotton fabric, DTG printing is likely your best bet. Understanding these differences helps businesses strategically determine which printing method aligns with their objectives.

Both DTF and DTG have their unique applications. DTF printing excels in versatility, allowing businesses to print on a variety of fabric types that include polyester and blends with solid color performance and durability. This flexibility is particularly beneficial for businesses that sell custom apparel or merchandise that need to cater to diverse fabric requirements. Conversely, the DTG method is ideal for designs that demand high fidelity and intricate artworks, making it a preferred choice for artists and fashion designers who aim to create statement pieces with stunning visual appeal. In choosing a method, it’s essential to assess the kinds of products you intend to offer in relation to your target market’s desires.

Frequently Asked Questions

What are the key DTF printing advantages over DTG printing?

DTF printing advantages include its versatility on various fabric types, durability of prints, and lower initial equipment investment, making it an excellent option for businesses looking for cost-effective printing solutions.

How does the DTG print quality compare to DTF printing?

DTG print quality is renowned for its exceptional detail and vibrant colors, especially on light fabrics. While DTF offers good quality, DTG excels in producing photorealistic prints, making it ideal for intricate designs.

Which is the best printing method for business: DTF or DTG printing?

The best printing method for business depends on specific needs. DTF is preferred for versatility and cost-effectiveness, while DTG is favored for high-quality prints, especially when detailed designs are required.

Are DTF printing solutions more cost-effective than DTG?

Yes, DTF printing solutions can be more cost-effective, especially for small runs or multi-color designs due to lower ink usage and waste, making it budget-friendly for startups.

What fabric printing techniques are utilized in DTF vs DTG printing?

DTF printing utilizes a transfer film method appropriate for various fabrics, including polyester, while DTG printing employs direct inkjet technology specifically designed for cotton fabrics.

What should businesses consider when choosing between DTF vs DTG printing?

Businesses should consider factors like cost efficiency, desired print quality, market demand, budget, and equipment space when choosing between DTF and DTG printing methods.

| Printing Method | Process | Suitable Fabrics | Advantages | Best For |

|---|---|---|---|---|

| DTF (Direct to Film) | Prints onto a coated film, transferred using heat. | Polyester, cotton blends, dark fabrics. | Versatility, durability, lower equipment cost. | Businesses seeking vibrant prints on various fabrics. |

| DTG (Direct to Garment) | Uses inkjet technology to print directly on fabric. | Primarily cotton fabrics. | Exceptional print quality, quick turnaround, eco-friendly inks. | Designers needing high-quality detailed artwork. |

Summary

DTF vs DTG printing presents business owners with distinct choices that can shape their product offerings. While DTF provides versatility and lower start-up costs, DTG excels in delivering high-quality prints suitable for detailed designs. Understanding these two printing methods allows brands to cater to their customer preferences effectively and meet the demands of the textile market. Ultimately, the right choice depends on factors like fabric type, print quality requirements, and operational budget, ensuring that businesses can confidently adopt the most suitable printing solution.