DTF Transfers, or Direct-to-Film Transfers, are rapidly becoming the go-to method for high-quality printing on textiles, revolutionizing the way designs are applied to fabric. This innovative technique allows both seasoned professionals and beginners to create stunning, vibrant prints on a variety of fabrics with remarkable ease. As we dive deeper into our DTF printing guide, you’ll discover the essential steps on how to do DTF transfers effectively, as well as the myriad benefits of DTF transfers that make them appealing to entrepreneurs and hobbyists alike. Whether you’re looking to elevate your apparel line or simply explore new creative avenues, understanding DTF printing offers a treasure trove of opportunities. Join us as we embark on this exciting journey into the world of eco-friendly DTF transfers, ensuring you have all the information you need to get started on your printing projects.

Known as Direct-to-Film printing, DTF Transfers represent a modern approach to applying graphics onto various fabrics, promoting creativity and customization in the apparel sector. This technique utilizes a unique film that allows the transfer of water-based inks, producing designs that are both colorful and intricate. Whether referred to as eco-conscious transfer printing or advanced film application, the versatility of DTF technology caters to a wide range of materials, making it ideal for a diverse audience of crafters and business owners. As we explore this effective method, from understanding ‘how to execute DTF transfers’ to appreciating the ‘benefits of utilizing DTF methods’, the insights provided will enhance your familiarity with this art form. Embracing DTF printing for beginners opens up a realm of possibilities, making it a valuable addition to your printing toolkit.

Understanding DTF Printing: A Beginner’s Perspective

Direct-to-Film (DTF) printing has become a popular choice for those looking to personalize fabrics with vibrant designs. For beginners, understanding the fundamentals of DTF transfers is vital to make the most out of this technique. It utilizes specialized films and eco-friendly inks, which eliminate the need for excessive water and chemicals, making it a sustainable option compared to traditional methods. Learning the intricacies of this process can open up new creative avenues for beginners.

Moreover, the beginner’s journey in DTF printing should start with familiarizing oneself with the essential tools and equipment. A DTF printer, specialized film, and heat press are the primary requirements. Understanding how to manipulate design software is equally crucial, as a well-prepared digital file will lay the foundation for stunning fabric prints. Exploring these aspects will equip newcomers with the confidence needed to produce quality DTF transfers.

Frequently Asked Questions

What are DTF Transfers and how do they work?

DTF Transfers, or Direct-to-Film Transfers, allow you to print intricate designs onto a specialized film using eco-friendly water-based inks. The design is then heat-pressed onto fabric, producing vibrant and durable prints. This process is distinct from traditional methods and offers a versatile solution for various textiles.

How do I get started with DTF printing for beginners?

To start with DTF printing as a beginner, you’ll need a DTF printer, transfer film, and adhesive powder. Begin by designing your graphics, print them onto the transfer film, coat with powder, cure, and then heat press onto your fabric. This step-by-step DTF printing guide simplifies the process for newcomers.

What are the benefits of using DTF transfers for fabric printing?

The benefits of DTF transfers include their versatility across different fabric types, exceptional vibrancy and detail in colors, and durable prints that withstand washing. This makes DTF an attractive option for creating customized clothing and other textile products.

Can DTF Transfers be eco-friendly?

Yes, DTF Transfers can be eco-friendly as they utilize water-based inks and sustainable materials. Many brands are now focusing on environmentally conscious practices within DTF printing, catering to consumers who prioritize sustainability in their purchasing decisions.

What settings do I need for a DTF printer?

For optimal results with a DTF printer, ensure you configure it according to the manufacturer’s specifications, typically selecting settings that accommodate the type of transfer film and inks you are using. It’s crucial to adjust the ink density and print quality to achieve vibrant outputs.

What is the curing process in DTF Transfers?

The curing process in DTF Transfers involves heating the printed film to solidify the adhesive powder onto the ink. This step is essential for ensuring the longevity and adherence of the print when applied to fabric, typically conducted using a heat press or oven.

| Step | Description |

|---|---|

| 1. Design Creation | Create graphics using software like Adobe Illustrator, ensuring a compatible file format with a transparent background. |

| 2. Film Printing | Use a DTF printer to print designs onto special transfer film with water-based inks. |

| 3. Powder Coating | Coat the wet printed film with adhesive powder to facilitate image adhesion during heat pressing. |

| 4. Curing | Heat the printed film to solidify the powder onto the ink, ensuring durability post-transfer. |

| 5. Heat Pressing | Align the transfer film onto the garment, set the heat press to 320°F (160°C), and press for 10-15 seconds. |

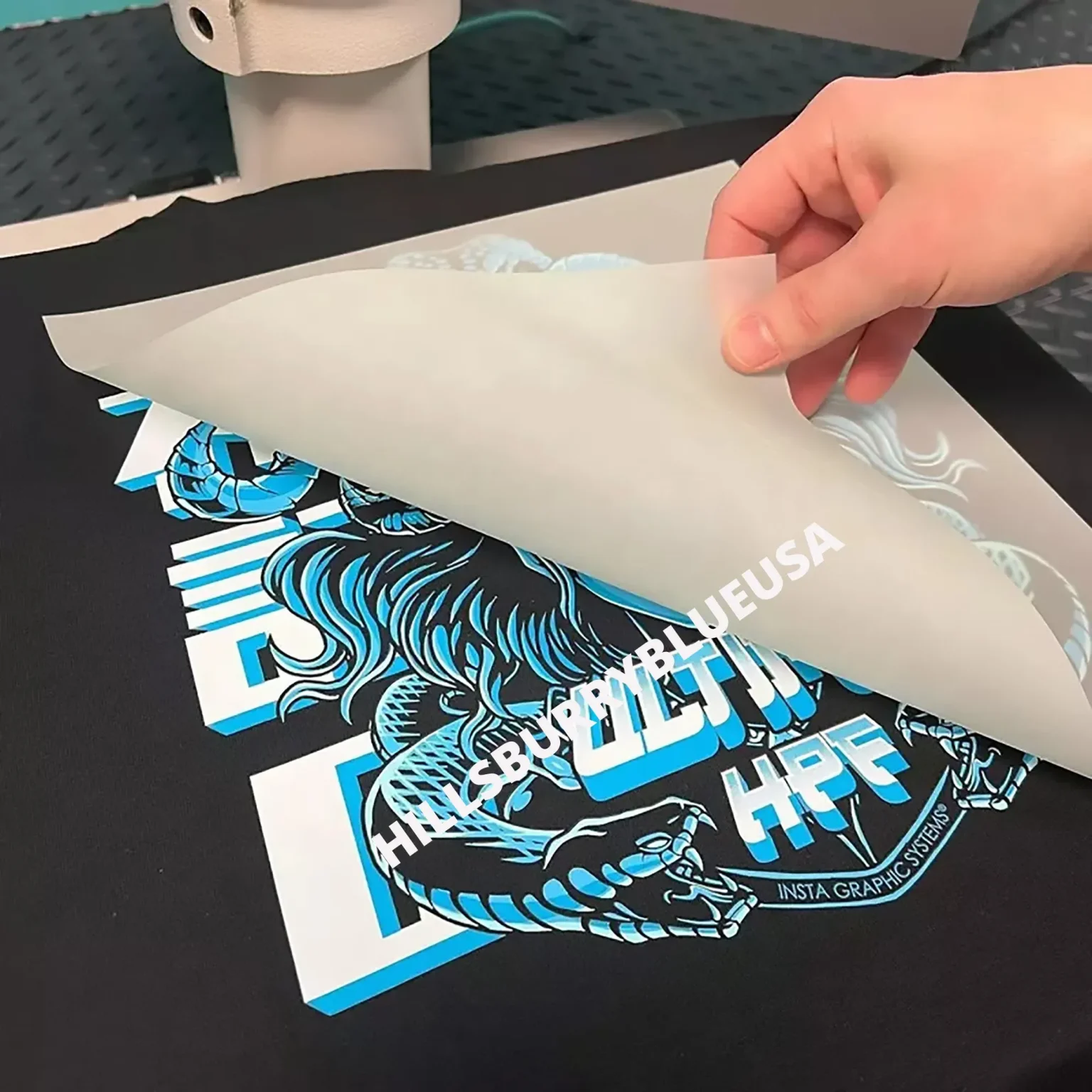

| 6. Post-Pressing Care | Allow the garment to cool before peeling off the transfer film, and follow care instructions for longevity. |

Summary

DTF Transfers are a transformative approach in fabric printing that cater to both novices and seasoned creators. This technique not only enables vibrant and intricate designs but also guarantees durability across various fabrics. As the landscape of DTF printing grows, now is the perfect time to adopt this innovative method, whether for business applications or personal projects. With an array of benefits that include eco-friendly options and increased accessibility to materials, DTF Transfers stand out as a go-to choice for anyone looking to enhance their printing capabilities.