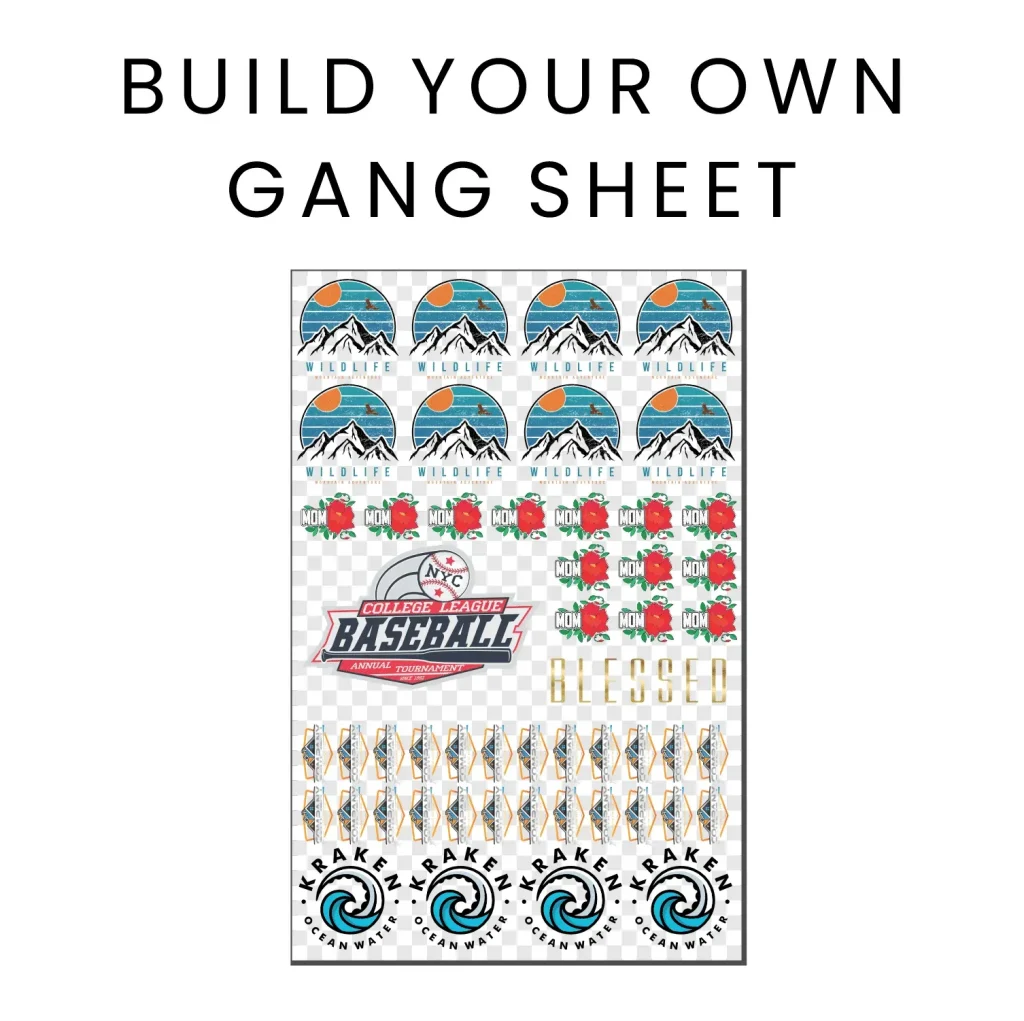

The DTF Gangsheet Builder is an essential tool for businesses seeking to optimize their custom printing processes. In the realm of Direct-to-Film (DTF) printing, this innovative method significantly enhances efficiency, allowing printers to organize multiple designs onto a single gangsheet. By minimizing material waste and maximizing print runs, the DTF Gangsheet Builder revolutionizes how textile printing is approached. This article will delve into practical tips and tricks for optimizing your prints, ensuring you achieve striking visuals while maintaining high standards of quality. If you’re passionate about printing optimization and want to create standout designs, mastering the DTF Gangsheet Builder is a must.

Exploring the concept of the DTF Gangsheet Builder reveals its integral role in enhancing printing capabilities for custom designs. This process, often referred to as gangsheet printing, allows multiple graphics to be printed on a single film sheet, streamlining production and conserving materials. As businesses dive into the realm of textile printing, understanding the nuances of this technique can lead to impressive results and cost-saving benefits. By employing strategic printing optimization methods and leveraging the power of custom prints, you can significantly elevate your output quality and efficiency. The need for effective design solutions in today’s competitive market makes grasping the intricacies of gangsheet building more important than ever.

Maximizing Quality with DTF Gangsheet Builder Techniques

When it comes to creating top-notch prints using a DTF gangsheet builder, implementing effective design techniques is essential. The use of vector graphics ensures that every design remains sharp and clear, even when resized for different applications. This is crucial for maintaining the quality of custom prints on textiles, as a well-defined design translates to vibrant prints that attract attention. Additionally, ensuring adequate spacing between each design will prevent overlapping, which can mar the final outcome and lead to unnecessary material waste. Paying attention to these details will amplify the visual impact of your printed products.

Moreover, consider optimizing the layout of your gangsheet for maximum efficiency. Aligning your designs in a systematic manner not only saves film but also streamlines the printing process. The DTF gangsheet builder makes it easier to visualize the entire sheet, allowing you to arrange multiple designs in a cohesive way. This thoughtful organization minimizes setup time and fosters a smoother workflow, proving advantageous for large orders. By mastering these techniques, you can enhance productivity while delivering exceptional quality that meets market demands.

Essential Color Management Practices for DTF Printing

Effective color management is a cornerstone of successful DTF printing. Utilizing the correct ICC color profiles is instrumental for achieving accurate color representation. When you assign the appropriate profiles tailored to your specific printer and ink set, the colors in your final prints will closely match the original designs. This is critical not only for visual appeal but also for satisfying customer expectations, particularly in custom textile applications where color accuracy is paramount.

Regular calibration of your printing equipment further solidifies your color management process. By routinely conducting color tests, you ensure that every print run yields consistent results, thereby establishing trust with your clientele. Consistency in color reproduction is especially important in bulk orders and merchandise that must meet branding standards. Through diligent color management practices, DTF printing can achieve remarkable results that are both vibrant and true to life.

Optimizing Print Settings for High-Quality Outputs

Optimizing your print settings plays a crucial role in the quality and efficiency of DTF prints. The resolution settings should be adjusted to a minimum of 300 DPI to guarantee that each detail is captured during printing. While higher resolutions can be tempting for producing stunning visuals, they may also significantly increase printing times. Finding the right balance between detail and efficiency is key, especially for businesses with tight production schedules.

Additionally, implementing layering techniques can elevate the final output of your prints. DTF printing excels in producing intricate designs by utilizing multiple transparent layers. This method not only enhances the vibrancy of colors but also adds texture to the printed design, resulting in visually striking products. Leveraging these advanced print settings allows for the creation of custom prints that truly stand out in the competitive textile printing market.

Choosing the Right Materials for Optimal DTF Printing

The selection of appropriate materials is fundamental in the DTF printing process. Various types of transfer films present different benefits that can influence the final print quality. For instance, glossy films often enhance the vibrancy of colors, making designs appear more lively and attractive, while matte finishes can impart a more sophisticated look. Additionally, experimenting with different film types can help identify which materials yield the best results for specific applications.

Equally important is the choice of adhesive powder, which affects the durability and longevity of the print. A well-chosen adhesive will ensure that the prints withstand washes and wear, ultimately contributing to customer satisfaction. Understanding the dynamics between various materials and adhesives can greatly impact the overall success of your DTF prints, allowing you to provide high-quality, durable products that meet both aesthetic and functional expectations.

Enhancing Efficiency with Software Solutions for DTF Printing

The use of specialized software for DTF printing can greatly enhance both efficiency and print quality. Many DTF software solutions come equipped with features specifically designed for creating gangsheet layouts, which facilitate the organizing of multiple designs in one print run. This capability not only saves time during the setup phase but also minimizes material waste by optimizing space on the transfer film.

Regular updates to your printing software are also crucial for maintaining optimal performance. Developers continuously improve functionalities, which can introduce new features that enhance your printing capabilities. Keeping your software current not only ensures compatibility with the latest operating systems but also provides access to improved tools for design and layout management. By leveraging modern software solutions, you can streamline the printing process, resulting in faster turnaround times and higher-quality outputs.

Connecting with the DTF Community for Ongoing Learning

Joining online communities and forums dedicated to DTF printing can significantly benefit those looking to enhance their skills and knowledge. Platforms like Reddit and Facebook host groups where both novice and experienced printers share insights, techniques, and experiences related to DTF gangsheet printing. Engaging in these communities allows you to access a wealth of knowledge, from asking for advice on specific challenges to finding inspiration for innovative designs.

In addition to online communities, participating in webinars and workshops hosted by industry professionals can provide invaluable learning opportunities. These events often cover advanced DTF printing techniques, market trends, and best practices, equipping you with the skills necessary to stay competitive in the custom printing landscape. By actively seeking learning opportunities, you will enhance your expertise in DTF printing and continuously improve your craft.

Frequently Asked Questions

What is a DTF Gangsheet Builder and how does it benefit DTF printing?

A DTF Gangsheet Builder is a tool that allows textile printers to arrange multiple designs on a single film sheet for Direct-to-Film (DTF) printing. This method enhances operational efficiency by minimizing material waste and reducing printing costs. By using a gangsheet builder, you can maximize production output and streamline the printing process.

How can I optimize my custom prints using a DTF Gangsheet Builder?

To optimize your custom prints with a DTF Gangsheet Builder, focus on design efficiency by using vector graphics and ensuring proper spacing between designs. Additionally, manage color profiles accurately, set high print resolutions, and choose the right materials and adhesives. Utilizing specialized software can also enhance your gangsheet layout.

What is the importance of color management in DTF printing with a gangsheet?

Color management is essential in DTF printing as it ensures that the final printed colors closely match the digital designs. Applying the correct ICC profiles and regularly calibrating your printer will help maintain consistency and accuracy across print runs, resulting in high-quality outputs.

What are the best materials for DTF printing using a gangsheet?

The best materials for DTF printing include high-quality transfer films and suitable adhesive powders. Depending on your design preferences, you may choose between matte and glossy finishes, with glossy often enhancing color vibrancy. Ensuring proper adhesive selection is crucial for durability and washability of the prints.

How do I ensure high-quality prints with a DTF Gangsheet Builder?

To ensure high-quality prints with a DTF Gangsheet Builder, set your printer’s resolution to at least 300 DPI for detailed outputs. Incorporate layering techniques in your designs to achieve depth and rich colors. Regularly test your printer and maintain optimal settings to achieve consistent results.

Where can I find resources to improve my DTF gangsheet printing skills?

You can find resources to improve your DTF gangsheet printing skills through online tutorials, community forums like Reddit, and industry webinars. Engaging with other DTF printing enthusiasts and professionals can provide valuable insights and tips for enhancing your printing techniques.

| Key Area | Tips |

|---|---|

| Design Efficiency | Use vector graphics; maintain spacing of 1-2 inches between designs. |

| Color Management | Utilize correct ICC profiles and perform regular color tests. |

| Print Settings Optimization | Set DPI to 300 and use layering techniques for detail. |

| Material Selection | Experiment with different film types and use suitable adhesive powder. |

| Software Utilization | Utilize specialized DTF software and keep it updated. |

Summary

DTF Gangsheet Builder is a game changer in the realm of custom printing, allowing for efficient production of high-quality designs. By mastering design efficiency, color management, print settings, and material selection, printers can optimize their output significantly. These practices not only enhance the visual impact of designs but also streamline the printing process, ensuring that each print run is as effective as possible. Embracing DTF printing fully, along with appropriate software and community support, ensures a competitive edge in the vibrant marketplace of custom textiles.