The DTF gangsheet has revolutionized the world of custom apparel printing, making it easier for decorators to produce vibrant designs efficiently. By leveraging the Direct to Film (DTF) printing method, users can print multiple designs on a single gangsheet, optimizing both material usage and costs. Whether you’re a seasoned printer or a beginner, understanding how to effectively set up a DTF gangsheet is crucial for maximizing your output and quality. This guide offers essential DTF tips for beginners, including insights on gangsheet setup, heat pressing DTF, and innovative transfer techniques. With the right knowledge, you can streamline your DTF process and elevate your print projects to new heights.

In the realm of custom garment decoration, the concept of gangsheet printing has gained immense popularity, particularly through the Direct to Film (DTF) technique. This method allows for the simultaneous transfer of various designs onto fabric, making it an efficient choice for both amateur and professional printers. As you delve into the intricacies of DTF gangsheet production, it’s vital to familiarize yourself with related aspects such as heat pressing, transfer methods, and the unique benefits of this printing technology. Adopting effective DTF techniques can significantly enhance your printing projects, enabling you to create stunning apparel that stands out. By understanding these fundamentals, you will set yourself on a path toward successful DTF printing endeavors.

The Basics of DTF Printing: What You Need to Know

Understanding the Direct to Film (DTF) printing process is essential for both beginners and seasoned decorators. DTF printing leverages groundbreaking technology to transfer intricate designs directly onto fabrics, bringing visuals to life in a vibrant and striking manner. Unlike traditional printing methods, DTF utilizes special inks that bond well with heat and fabric, making it a preferred choice for both small-scale and larger productions. With DTF, custom apparel decorators can achieve bold colors and detailed designs without compromising on quality.

The versatility of DTF printing is another compelling aspect. Whether working with cotton, polyester, or blends, DTF accommodates a wide range of materials, opening up possibilities for various apparel items from t-shirts to hoodies. For beginners, grasping the fundamentals of DTF is key to leveraging its potential for creating unique custom designs that capture the essence of your artistic vision.

Setting Up Your DTF Gangsheet for Optimal Results

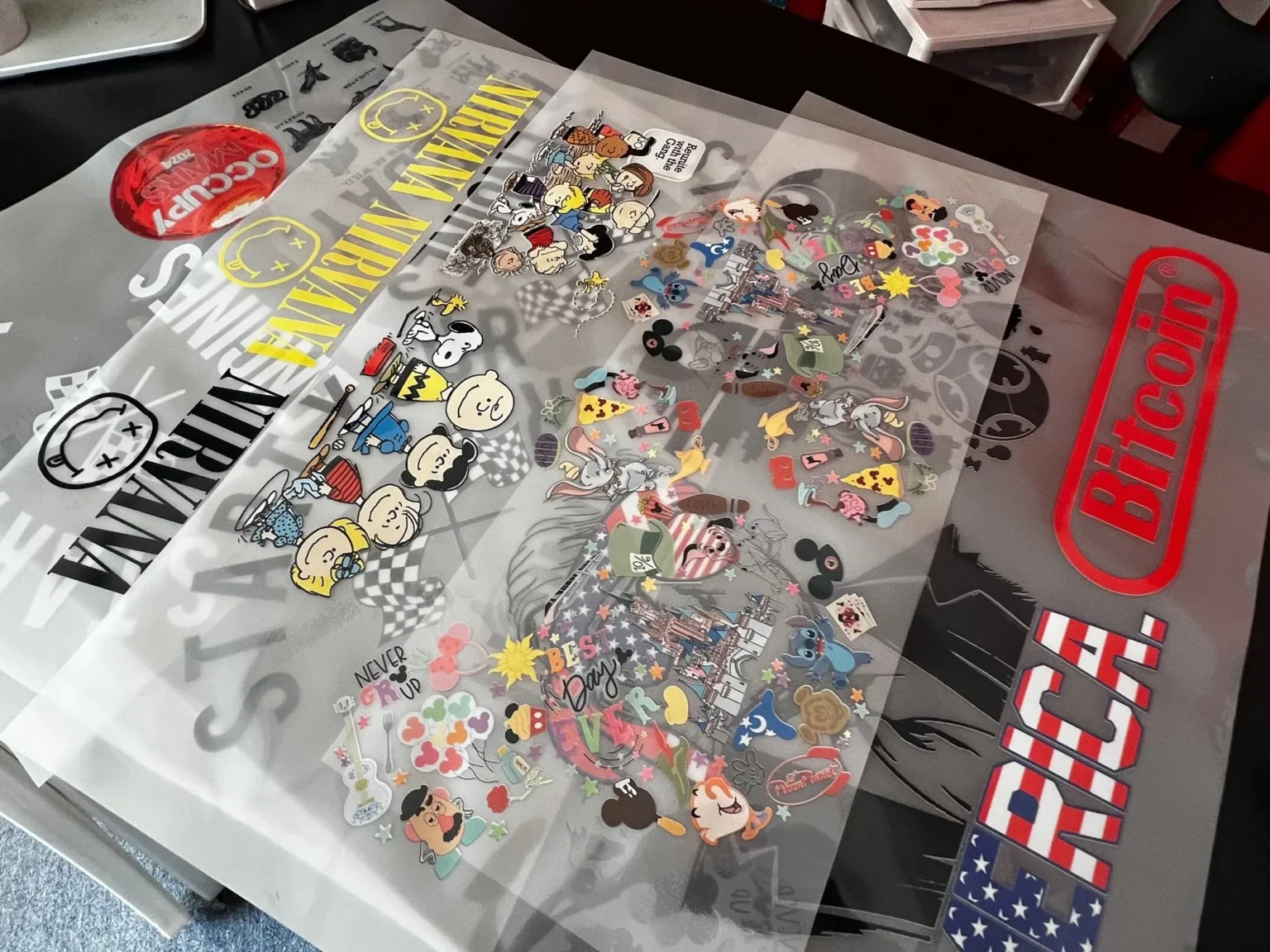

Creating a gangsheet in DTF printing is an essential technique that significantly boosts efficiency. The gangsheet setup allows multiple designs to be printed on a single sheet of film, dramatically reducing costs and maximizing material usage. Beginners should focus on user-friendly software tools that facilitate this process, such as Adobe Illustrator, which helps ensure accurate layout and scaling for each design. This practice not only enhances the quality of prints but also levels up your overall printing strategy.

When arranging your designs on the gangsheet, consider critical factors like spacing and design sizes. Proper spacing prevents overlap and ensures each design retains its quality during the heat transfer process. Mixing various design sizes can also optimize testing capabilities and material usage, which is particularly valuable for novice printers experimenting with different styles.

Design Tips for Successful DTF Printing

The quality and detail of your designs are paramount when embarking on DTF printing. Beginners should ensure that all images are created at a resolution of at least 300 DPI (dots per inch) to guarantee high-quality outputs. Any design lacking in resolution will produce blurry images, which can be detrimental to the finished product. Moreover, utilizing transparent backgrounds is highly recommended as it minimizes ink usage and enhances the vibrancy of the final prints.

Additionally, understanding color profiles is crucial in DTF printing. Familiarize yourself with the CMYK color model, which aligns well with the DTF transfer process. Experiments with different colors can help newcomers refine their designs, leading to a better grasp of how colors translate through the heat transfer technique. This knowledge will not only improve your outcomes but also boost your confidence as you dive deeper into custom design creation.

Choosing the Right Inks for DTF Success

Selecting high-quality DTF inks is pivotal in achieving optimal printing results. Inks such as those offered by Aurora DTF are known for their vibrancy and longevity, ensuring that your designs remain eye-catching over time. For beginners, prioritizing reputable brands is essential; using poor-quality inks can lead to dull or inconsistent printing, ultimately impacting your work’s overall professionalism.

Handling the inks correctly is equally important. Ensure that you apply the right amount of hot melt powder before the transfer, as this material plays a crucial role in ensuring a strong bond between your printed design and the fabric. Furthermore, experimenting with various brands and formulations can reveal which types yield the best results for different fabric types, enhancing your adaptability and skill level in the DTF printing process.

Mastering Heat Pressing for DTF Transfers

Heat pressing is a critical stage in the DTF printing workflow that can make or break the quality of your final product. Beginners should understand the correct temperature and timing settings to ensure proper adhesion of the transfer to the fabric. Typically, a heat press should operate at around 320°F (160°C) for 10-15 seconds, although slight adjustments may be necessary depending on the specific fabric type and thickness. Understanding these nuances is vital for achieving professional results.

Moreover, consistent pressure application during the heat press process is key to avoiding uneven transfers. Calibrating your heat press can significantly improve outcomes, as it ensures that pressure is applied uniformly across the garment. When layering multiple designs, it’s crucial to allow each transfer to properly cure before applying additional layers, as this prevents misalignment and ensures a polished finish to your work.

Post-Printing Care: Preserving Your DTF Designs

After applying DTF transfers, proper post-printing care is essential for maintaining the vibrancy and integrity of your designs. Allowing the printed garments to cure for a minimum of 24-48 hours before washing helps solidify the bond between the ink and fabric, resulting in a longer-lasting outcome. Beginners should adopt this step as a routine practice to ensure their high-quality work continues to look great over time.

Furthermore, washing instructions play a vital role in the longevity of DTF transfers. Always washing garments inside out and using cold water can minimize wear on the transfer, protecting both the integrity of the print and the fabric itself. Adhering to these care instructions will not only extend the life of your designs but also enhance customer satisfaction, turning new buyers into repeat customers.

Frequently Asked Questions

What is a DTF gangsheet and how does it work in DTF printing?

A DTF gangsheet is a large printing sheet that allows multiple designs to be printed simultaneously using DTF printing technology. This setup maximizes material usage and reduces printing costs, making it ideal for custom apparel decorators.

What are effective tips for setting up a DTF gangsheet for beginners?

When setting up a DTF gangsheet, beginners should use user-friendly design software like Adobe Illustrator for layout optimization, ensure proper spacing between designs to prevent overlap, and utilize transparent backgrounds to enhance the final print quality.

How does heat pressing work with DTF gangsheet transfers?

Heat pressing for DTF gangsheet transfers involves applying the correct temperature (generally around 320°F for 10-15 seconds) and maintaining consistent pressure to ensure that the DTF prints adhere properly to the fabric, producing vibrant, long-lasting designs.

What are some common DTF tips for beginners to avoid common mistakes?

Beginners should focus on high-resolution images (at least 300 DPI), test various inks for the best adhesion, and allow proper curing time of 24-48 hours before washing to ensure the longevity of DTF prints.

How do I choose the right DTF inks for my gangsheet projects?

When selecting DTF inks, opt for high-quality brands like Aurora DTF that produce bright colors, and conduct tests with different ink formulations to find the one that best suits your specific fabrics and desired print outcomes.

What maintenance is required for garments made with DTF gangsheet transfers?

To maintain DTF gangsheet transfer prints, turn garments inside out before washing, use cold water, and allow at least 24 hours of curing time after printing to ensure that the ink adheres properly to the fabric.

| Key Point | Description |

|---|---|

| Understanding DTF Printing | DTF printing uses digital imaging to transfer designs onto fabrics, allowing for vibrant colors and efficiency. |

| Core Components | Key tools include a DTF printer, DTF inks, and a heat press for transferring designs. |

| Setting Up Your Gangsheet | A gangsheet allows multiple designs to be printed at once, maximizing material usage and reducing costs. |

| User-Friendly Software | Programs like Adobe Illustrator and CorelDRAW help in creating effective gangsheet layouts. |

| Design Tips | Ensure designs are high resolution with transparent backgrounds and familiarize yourself with color profiles. |

| Ink Quality | Using high-quality inks, like those from Aurora DTF, will result in brighter colors and durability. |

| Heat Press Techniques | Maintain proper settings and pressure during heat pressing to ensure even transfers. |

| Post-Printing Care | Allow garments to cure before washing and use cold water while washing to preserve designs. |

Summary

DTF gangsheet is a pivotal tool for anyone venturing into the world of Direct to Film printing. Understanding how to effectively create and utilize a gangsheet will drastically improve the efficiency and quality of your custom apparel projects. This comprehensive guide outlines essential techniques, such as optimizing software use, adhering to proper heat pressing methods, and ensuring meticulous post-printing care. By mastering these elements, you will not only enhance your printing skills but also deliver vibrant, durable designs that stand out in the market.