DTF transfers, or Direct to Film transfers, are increasingly revolutionizing the apparel printing landscape with their impressive capabilities. These innovative custom transfers allow for vibrant designs to be printed onto special films which are then seamlessly transferred onto various fabrics, including cotton and polyester. As brands and consumers seek high-quality printing solutions, the adoption of DTF printing technology has surged, positioning it as a leader in printing innovations. With advantages such as versatility and durability, DTF transfers are easily gaining a foothold in the market. This article explores the growing popularity of DTF technology and its significance in the future of apparel printing.

In the realm of apparel decoration, DTF transfers—also known as Direct to Film printing—are fast becoming a preferred method for high-quality graphic applications. This state-of-the-art printing technique enables detailed designs to be transferred onto fabrics, capturing the nuances of color and clarity like no other method. Many in the industry are leveraging these custom transfer solutions to cater to the diverse demands of consumers. As an alternative to traditional methods like sublimation, DTF offers unprecedented versatility, making it highly sought after for custom apparel production. The increasing advancements in this innovative printing technology are reshaping how creatives and brands approach garment decoration.

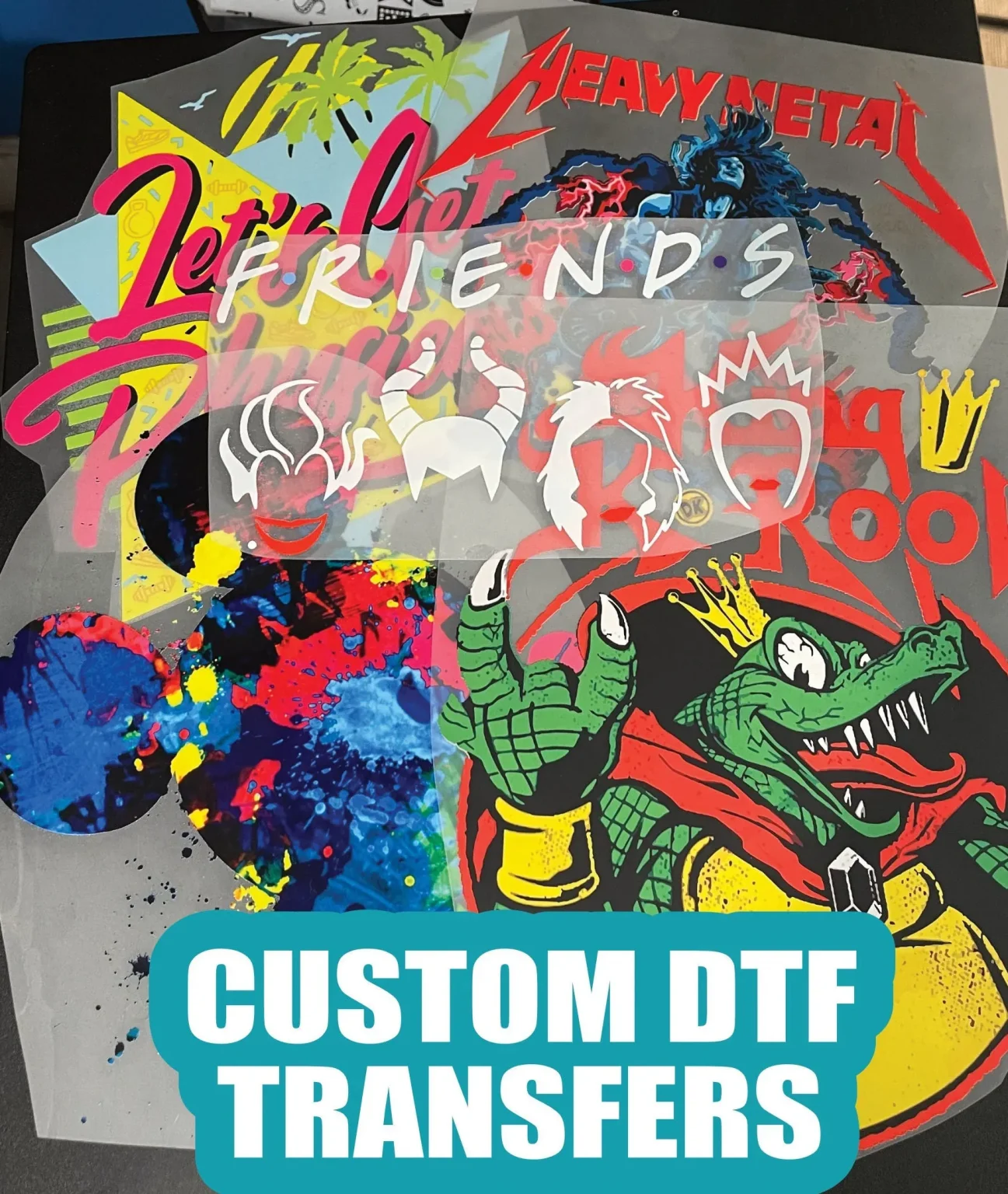

Understanding DTF Transfers: A Closer Look

DTF (Direct to Film) transfers represent a significant advancement in the apparel printing sector, providing an efficient solution for custom designs. Unlike traditional methods that often limit materials or color options, DTF printing allows designers to create vibrant artwork that adheres well to a wide array of fabrics, including those that are typically challenging to print on, such as dark garments. This versatility not only empowers brands to expand their product offerings but also aligns with current consumer demands for unique, personalized apparel.

The process of DTF transfer involves printing high-quality images onto a specially coated film that is then applied to fabric using heat and pressure. This method ensures that the prints are durable and long-lasting, addressing one of the major concerns among apparel manufacturers regarding print longevity. As more brands discover the benefits of DTF technology, the demand for this innovative printing method is growing, making it an essential consideration for anyone involved in apparel production.

The Rise of Premium DTF Transfer Services

Recent developments in the DTF printing landscape have led to the emergence of premium in-house DTF services, such as those launched by Sam’s DTF Transfers. This trend responds to the increasing demand from e-commerce businesses and small brands seeking customized printing solutions without the burden of minimum order requirements. By facilitating small batch runs, these services allow brands to remain agile in a rapidly changing market, ensuring they can meet customer needs quickly and efficiently.

This shift towards premium DTF services reflects a broader trend in the custom apparel industry where personalization and flexibility are key. Brands can now offer their clients bespoke designs and swift turnaround times, leveraging the capabilities of DTF printing technology to enhance customer satisfaction. This focus on in-house production not only simplifies the logistics of print orders but also encourages creativity and innovation in designs that appeal to diverse consumer bases.

Innovations in DTF Products: What’s New?

Innovative products like the Insta DTF heat transfer developed by Insta Graphic Systems are setting new standards within the apparel printing world. With enhancements in vibrancy and durability, these innovations are addressing common issues related to print fading and wear. The focus on creating high-quality, long-lasting products is crucial as it ensures that brands can provide their customers with the best value while also maintaining high standards for their merchandise.

The introduction of advanced DTF products signifies a commitment to continual improvement within the industry. As brands and manufacturers adopt these innovations, they not only improve their offerings but also enhance their competitive edge in the market. Custom designs printed with high-quality DTF technology are likely to attract more customers, thus solidifying this printing method as a key player in custom apparel trends.

Comparing DTF Printing to Sublimation Techniques

The distinction between DTF printing and sublimation techniques plays a significant role in the decision-making process for many businesses. DTF printing offers the unique advantage of being applicable to a wider variety of fabrics, including dark and colored materials, which sublimation often cannot accommodate. As consumer preferences shift towards more unique and diverse apparel options, the flexibility of DTF printing positions it as a superior choice, particularly for small and custom orders.

As brands explore their printing options, understanding these differences can lead to more informed decisions. DTF’s capacity for addressing the challenges faced by traditional methods ensures that customers receive high-quality products tailored to their specific needs. The comparative analysis between DTF and sublimation highlights DTF’s position as a transformative force in custom apparel printing, appealing to a broader audience seeking quality and variety.

Custom Transfer Services: Catering to Creators and Crafters

The increasing popularity of DTF technology has led to the establishment of custom transfer printing services tailored specifically for creators and crafters. Companies like DTFPrinter have recognized the need for simplified ordering processes, helping individual artists and small businesses navigate the complexities of custom printing. This initiative not only addresses existing barriers but also encourages creativity by making high-quality printing accessible to a wider audience.

By streamlining the process, these services empower creators to focus on their designs and artistry rather than logistics. This shift allows for greater exploration of unique patterns and graphics, setting the stage for innovative apparel trends. As more creators embrace DTF technology, the market will likely witness a surge in diverse and creative apparel that resonates with individual consumer tastes.

The Bright Future of DTF in Apparel Printing

The future of DTF transfers in the apparel printing industry is undeniably bright, driven by technological innovations and increasing consumer demand for customization. As advancements in DTF printing technology continue to emerge, brands are positioned to leverage these developments to improve their offerings. The emphasis on quality and durability in prints is not just about maintaining standards; it’s about shaping the future landscape of apparel production.

Moreover, the flexibility and efficiency offered by DTF technology are crucial as brands navigate a more competitive marketplace where fast turnaround times and personalized options are essential. As the adoption of DTF printing grows among companies aiming to meet evolving consumer preferences, it stands as a testament to the continued evolution of apparel printing methodologies, paving the way for a dynamic and innovative future.

Frequently Asked Questions

What are DTF transfers and how do they work in apparel printing?

DTF transfers, or Direct to Film transfers, involve printing designs on specialized film that is then applied to fabric using heat and pressure. This versatile technology allows for vibrant and durable prints on various materials, including cotton and polyester, making it an ideal choice for custom apparel printing.

Why are DTF transfers becoming the preferred choice for custom apparel printing?

DTF transfers are gaining popularity due to their versatility, allowing for printing on dark and diverse fabrics, which is a limitation of traditional sublimation methods. Additionally, the vibrant colors and long-lasting quality of DTF prints cater to evolving consumer preferences in custom apparel.

What recent advancements have been made in DTF printing technology?

Recent advancements in DTF printing technology include the launch of premium in-house services without minimum order quantities and innovative products like the Insta DTF heat transfer, which enhances print durability and vibrancy. These developments mark a significant shift towards efficient and customer-centric printing solutions.

How does DTF printing compare to sublimation printing?

DTF printing offers significant advantages over sublimation, including the ability to print on dark fabrics and a wider range of materials. This flexibility makes DTF transfers particularly appealing for custom apparel, allowing brands to meet diverse consumer demands effectively.

What impact do DTF transfers have on the future of apparel printing?

DTF transfers are set to revolutionize the apparel printing industry by providing high-quality, efficient, and accessible printing solutions. As innovations continue and consumer demand for customization grows, DTF technology will likely play a pivotal role in shaping the future landscape of printing.

Are there any new services or products related to DTF transfers that benefit small businesses?

Yes, companies like DTFPrinter are launching custom transfer printing services to simplify the ordering process for creators and small businesses. These services, along with the introduction of no minimum order requirements, empower smaller brands to utilize DTF transfers effectively in their operations.

| Key Aspect | Description |

|---|---|

| What are DTF Transfers? | Printing designs onto special film for transfer to fabric, allowing vibrant color on various materials. |

| Emergence of Premium Services | Sam’s DTF Transfers offers in-house services without minimum order quantities catering to small brands. |

| Innovative DTF Products | Insta Graphic Systems launched Insta DTF heat transfer for improved color and durability. |

| Advanced DTF Technology | Mimaki UJV300DTF-75 roll-to-roll printer enhances efficiency and versatility in DTF application. |

| Consumer Interest Comparison | DTF’s ability to print on dark fabrics makes it preferred over sublimation for custom apparel. |

| Custom Transfer Services | DTFPrinter simplifies custom transfer printing for creators addressing common logistical issues. |

| Popularity Factors | Versatility, quality, efficiency, and accessibility drive the growing preference for DTF transfers. |

| Future Trends | DTF transfers are set to revolutionize apparel printing with further innovations and customization. |

Summary

DTF transfers are revolutionizing the landscape of apparel printing with their astounding flexibility, vibrant color reproduction, and increased efficiency. As the printing industry continues to evolve, DTF technology stands out as a preferred method due to its ability to produce high-quality prints on both light and dark fabrics. This versatility not only caters to a broad spectrum of customization needs but also allows small brands and creators the opportunity to thrive without heavy financial commitments. With constant advancements in technology, such as premium in-house services and innovative products, DTF transfers are not just shaping the present but also pointing towards a promising future in the custom apparel market.