DTF Transfers, or Direct-to-Film transfers, are revolutionizing the landscape of custom apparel printing by offering exceptional print quality and design versatility. This innovative printing process allows for detailed, vibrant images to be transferred onto a variety of fabrics, making it a favored choice for personalized garments and promotional merchandise. As we delve deeper into the DTF printing process, we will uncover how these transfers are made, the advanced DTF printing technology that powers them, and the sustainable printing methods incorporated into this cutting-edge technique. Not only do DTF Transfers provide impressive durability and wash resistance, but their environmental impact is also a priority, with many practitioners adopting eco-friendly inks and materials. Join us as we explore the nuances of DTF transfers and their growing significance in the world of custom apparel.

The process of Direct-to-Film (DTF) printing has gained immense popularity for its ability to streamline custom printing on textiles. Often hailed as a game-changer in the realm of fabric decoration, DTF technology allows for high-resolution designs to be applied seamlessly onto various materials, catering to both small-scale and large production needs. As we dive into this exciting area, commonly referred to as fabric transfer printing, we will unearth the intricacies of how these designs are produced, the equipment required for successful implementation, and the emerging trends in sustainable practices within this printing sector. With an increasing demand for personalized apparel and innovative promotional items, DTF printing represents a sustainable choice for modern businesses looking to make their mark. Explore with us the transformative role that DTF transfers play in enhancing the world of textile customization.

Exploring the DTF Printing Process

The Direct-to-Film (DTF) printing process stands as a versatile and effective method for producing vibrant designs on fabric. It begins with the creation of a digital graphic, which is crafted using advanced design software. This step is essential for achieving high-quality visuals, as the precision of the design directly impacts the final product’s aesthetic appeal. Once the digital design is perfected, it is printed onto a specialized transfer film. This film serves as the medium that carries the designs to the fabric during the heat transfer phase.

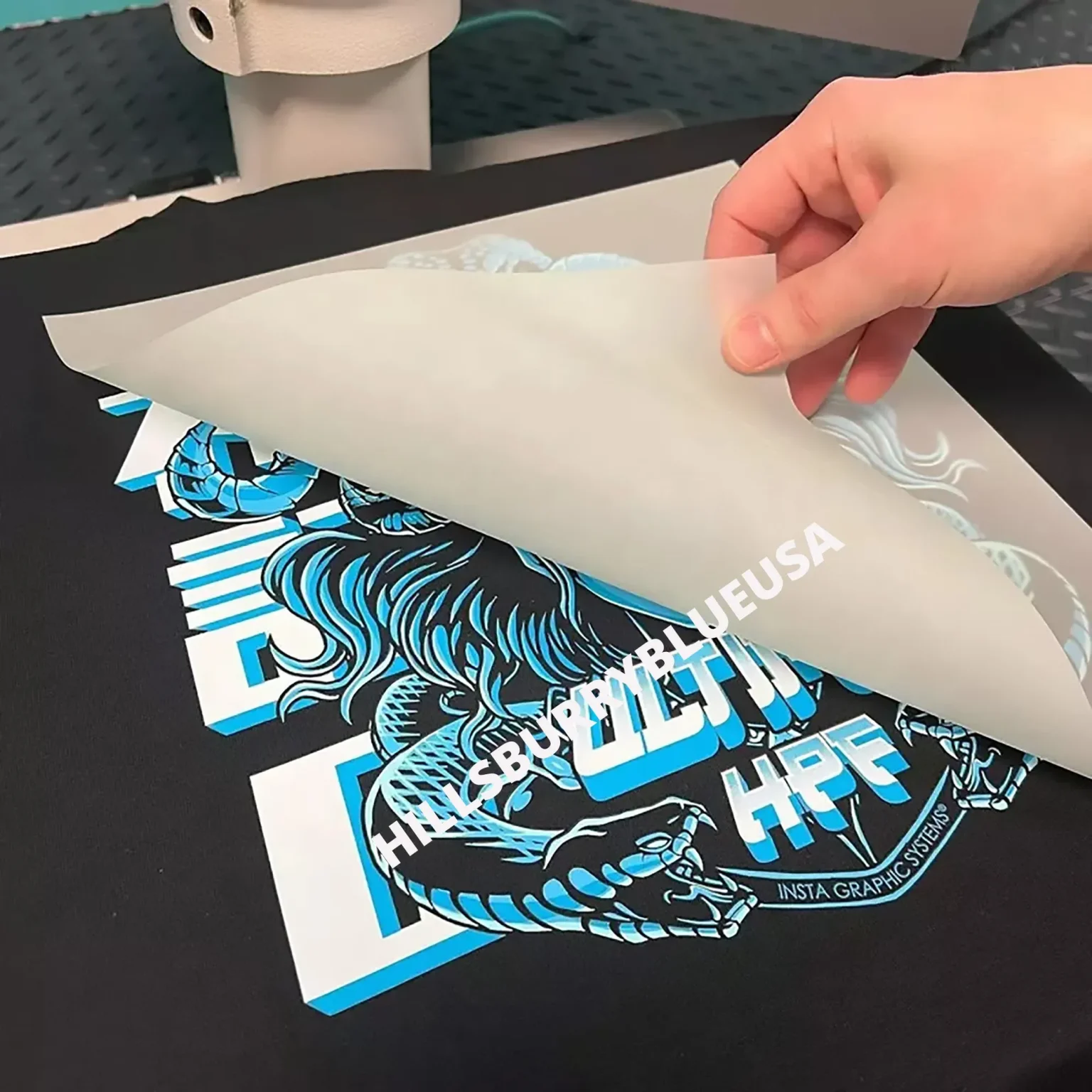

Next in the DTF printing workflow is the application of a hot-melt adhesive powder, which is applied to the printed film. This powder is critical because it creates a strong bond between the printed graphic and the fabric when subjected to heat. After the powder is applied, the film undergoes a curing process, where heat activates the adhesive, ensuring that the design adheres properly during the transfer. Finally, the cured film is positioned on the chosen fabric and subjected to heat and pressure from a heat press, resulting in a clear and durable print that can withstand washing and daily wear.

The Technology Behind DTF Transfers

DTF printing technology utilizes specialized printers designed explicitly for this purpose, equipped with unique ink formulations that enhance the transfer process. The inks used in DTF printing are typically water-based, which align with current sustainability trends and provide vibrant colors. These inks have improved qualities, including wash resistance and flexibility, making them ideal for various applications such as fashion apparel and home textiles. The specialized DTF printers ensure that the print quality is consistent and reliable, allowing for high-volume production without compromising on detail.

Moreover, the materials used in DTF printing, like high-quality transfer films and adhesive powders, significantly affect the final output. The choice of these materials is paramount as they contribute to the durability and visual appeal of the finished product. Manufacturers are continually innovating, leading to the development of biodegradable adhesives, which further enhances the eco-friendliness associated with DTF technology. This combination of advanced printing technology and high-quality materials positions DTF as a dominant player in the custom apparel market.

Custom Apparel Applications of DTF Printing

With its innovative approach, DTF printing stands out in the custom apparel market, offering businesses and designers the ability to create tailored clothing with ease. The versatility of DTF transfers means that they can be used on a wide range of fabrics, including cotton, polyester, and blends, making it suitable for diverse garment types like t-shirts, hoodies, and sportswear. This adaptability is a key reason why many brands are opting for DTF technology to meet the growing consumer demand for personalized apparel.

In addition to t-shirts and casual wear, DTF printing can also be utilized to create unique designs for promotional items, merchandise, and event-specific clothing. Businesses can effectively leverage DTF printing to produce customized promotional gifts like tote bags, caps, and accessories, thereby enhancing their branding efforts. The speed and efficiency of the DTF process allow for short turnaround times, which is ideal for companies needing to satisfy rapid order fulfillment or seasonal collections.

Sustainable Practices in DTF Printing

As sustainability becomes a crucial consideration in the textile industry, DTF printing technology is leading the charge with eco-friendly practices. A key feature of DTF printing is the use of water-based inks that eliminate the harmful effects associated with traditional solvent-based inks. These inks not only reduce toxicity for workers but also help businesses maintain a smaller environmental footprint, aligning with consumer preferences for sustainable product choices.

Furthermore, the development of biodegradable hot-melt adhesive powders represents another step toward making DTF printing more environmentally friendly. By minimizing the impact of print production on the environment, brands that adopt these sustainable practices can appeal to eco-conscious consumers. DTF printing’s efficiency and lower energy consumption also contribute to a reduced carbon footprint, positioning it as a responsible choice for modern businesses.

Future Innovations in DTF Printing Technology

The future of DTF printing looks promising, with continuous advancements in printing technology likely to enhance the efficiency, quality, and versatility of the process. One potential innovation is the integration of hybrid systems that combine the strengths of DTF printing with other techniques, such as Direct-to-Garment (DTG) printing. This could expand creative possibilities for designers, allowing for more complex and intricate designs on various substrates.

In addition to exploring hybrid systems, manufacturers are focused on improving production speeds and print quality. As technology progresses, we can expect to see faster DTF printers that maintain high standards of quality, reducing turnaround times for businesses. These advancements will help meet the increasing demand for customized products while ensuring that printers can handle larger volumes without sacrificing detail or durability.

Market Trends Shaping DTF Transfers

The DTF printing market has been experiencing significant growth, driven by an increasing demand for custom and personalized apparel. As consumers seek unique clothing options that reflect their individual styles, businesses are responding by adopting DTF technology for its ability to produce high-quality, customized prints quickly. This trend is particularly favorable for small businesses and startups looking to differentiate themselves in a competitive marketplace.

Moreover, the attractive pricing and lower initial investment requirements of DTF technology compared to traditional printing methods like screen printing and embroidery allow a broader range of companies to enter the custom apparel space. The combination of affordability and high-quality output makes DTF transfers an appealing choice for entrepreneurs aiming to capitalize on the growing trend of customized merchandise, from casual wear to promotional items.

Frequently Asked Questions

How are DTF transfers made during the printing process?

DTF transfers are made through a straightforward process that starts with creating a digital design, which is printed onto specialized transfer film using DTF printers. This film receives a layer of hot-melt adhesive powder, which is then cured with heat to activate adhesion before it is finally heat-pressed onto the fabric, resulting in high-quality prints.

What is the DTF printing process and how does it work?

The DTF printing process involves printing designs onto a transfer film, applying adhesive powder, and curing it through heat. The film is then used with a heat press to transfer the design onto textiles, allowing for vibrant, durable custom apparel designs.

What advantages does custom apparel DTF printing offer?

Custom apparel DTF printing offers advantages such as vibrant colors, excellent wash resistance, and compatibility with a variety of fabrics. This technology allows for quick production, personalization, and lower costs compared to traditional printing methods.

How does DTF printing technology support sustainable printing methods?

DTF printing technology supports sustainable printing methods by utilizing water-based inks, which are less harmful than solvent-based alternatives. Additionally, innovations in adhesive powders aim to develop biodegradable materials, reducing environmental impact.

What equipment is essential for effective DTF printing?

Essential equipment for effective DTF printing includes specialized DTF printers, quality heat press machines for transferring prints, and high-quality transfer films and hot-melt adhesive powders to ensure durability and print longevity.

What market trends are influencing the popularity of DTF transfers today?

Current market trends influencing the popularity of DTF transfers include the rising demand for custom apparel, affordability, and accessibility of DTF technology, enabling businesses and startups to produce personalized products quickly and economically.

| Key Point | Description |

|---|---|

| DTF Printing Definition | Direct-to-Film (DTF) printing allows for high-quality images to be printed on a special film and transferred onto textiles. |

| Process Steps | 1. Design Creation 2. Film Printing 3. Powder Application 4. Curing 5. Heat Transfer |

| Equipment Used | – DTF Printers – Heat Press Machines – Transfer Films and Adhesive Powders |

| Ink Technology | Water-based inks provide vibrant colors, enhanced wash resistance, and flexibility, ideal for various textiles. |

| Environmental Considerations | DTF uses eco-friendly water-based inks and may incorporate biodegradable powders and energy-efficient practices. |

| Market Trends | Growing demand for custom apparel and lower initial investment compared to traditional methods are fueling growth. |

| Applications | DTF is versatile, suitable for home decor and promotional items alongside clothing. |

| Future Outlook | Advancements may lead to hybrid printing systems and improvements in speed and quality. |

Summary

DTF Transfers are revolutionizing the custom printing landscape, blending exceptional quality with a streamlined process. This innovative technology offers unique capabilities that cater to the growing demand for personalized apparel and diverse product applications. By understanding how DTF transfers are made and their benefits, businesses and designers can stay ahead in the industry, embracing the future of printing with confidence.