DTF transfer papers are revolutionizing the custom printing industry, offering artists and small businesses a dynamic way to bring their creative visions to life. This innovative technology allows for exceptional printing on a variety of fabrics, delivering vibrant, detailed designs that stand out. As the demand for high-quality prints grows, finding the best DTF transfer papers becomes essential for those looking to elevate their craft. In this guide, we will explore the top DTF transfer papers available, provide insights on how to choose the right transfer paper for fabric, and offer tips specifically for DTF printing for artists. Whether you’re a beginner or a seasoned pro, understanding these materials will enhance your printing experience and the quality of your finished products.

Direct-to-film (DTF) transfer sheets have gained significant traction among printers and creatives, thanks to their ability to simplify the process of applying designs onto textiles. Known commonly as film transfer papers, these sheets facilitate the effortless transfer of intricate prints, making them a favorite for both large-scale and bespoke projects. As artists seek the optimal solutions for fabric printing, deciphering the key features of various DTF transfer sheets is vital. This discussion not only helps you navigate through different types effectively but also guides you towards achieving outstanding results in your printing endeavors. Let’s further dissect this topic and determine the best techniques for selecting suitable printing materials.

The Importance of DTF Transfer Papers

DTF transfer papers play a vital role in the custom printing landscape, offering artists and businesses an efficient method to produce eye-catching designs. The ability to print vibrant colors directly on various fabrics makes these papers indispensable for those looking to make their mark in the fashion industry. Not only do they allow for detailed and intricate graphics, but they also simplify the printing process significantly, reducing the time and effort required for setup compared to traditional methods.

Understanding the importance of choosing the right DTF transfer papers is crucial for achieving professional-quality prints. Different papers can drastically affect the outcome of your project, from the durability of the prints to the richness of the colors. This makes informed decision-making imperative for both hobbyists and professionals alike, ensuring that every design comes to life with precision and clarity.

How to Choose the Best DTF Transfer Papers

Selecting the best DTF transfer papers involves examining several factors that influence print quality and fabric compatibility. The choice between matte and glossy finishes is often the first decision to make; while glossy papers can enhance color vibrancy, matte papers offer a subtler appearance that may match certain design aesthetics better. Additionally, considering fabric compatibility is essential, as not all papers work equally well on every material. Investing time to test different combinations can ultimately lead to more successful outcomes.

Another critical element in choosing DTF transfer papers is understanding the print quality they yield. Some papers may absorb ink differently, affecting the vibrancy and detail of the prints. Users should prioritize brands known for producing high-quality papers that provide consistent results, particularly for intricate designs that require precision. By researching extensively and reviewing testimonials, artists can determine which DTF transfer papers align with their specific needs.

Top Brands to Consider for DTF Transfer Papers

The DTF transfer paper market is saturated with numerous brands, each offering unique characteristics. Among these, Hosea, A-SUB, Siser, and Epson have established themselves as leaders due to their reliability and quality. Hosea is especially revered for its superior adhesion, while A-SUB is known for producing sharp, vibrant images that satisfy a variety of fabric types. These brands cater to different user preferences, ensuring that both novice and experienced printers can find suitable options for their projects.

Epson’s legacy in the printing industry translates to its DTF transfer papers, specifically crafted to work seamlessly with Epson printers. This synergy between hardware and material optimizes print outcomes, allowing for hyper-detailed designs. Siser’s reputation for durability means that prints last through many washes, retaining both color and clarity, making it a top choice for those in the custom apparel business.

Understanding DTF Printing Techniques

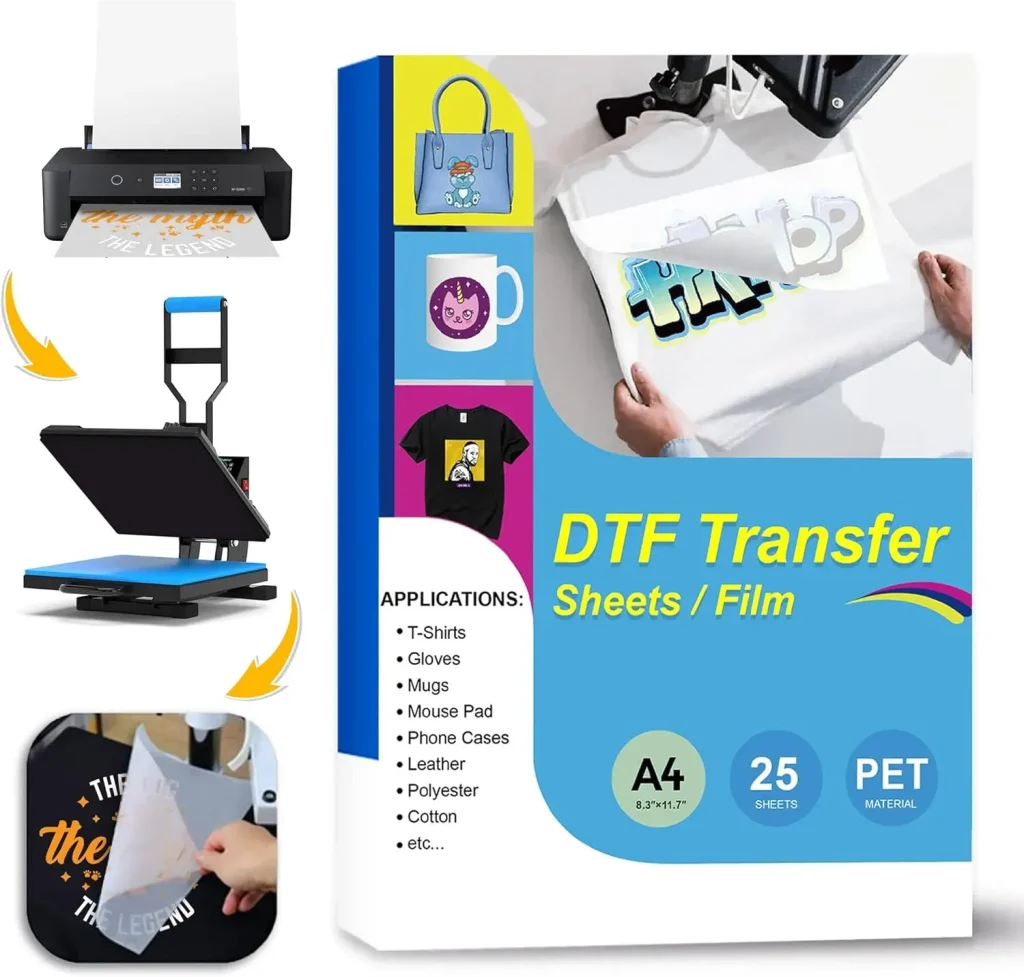

To fully harness the benefits of DTF transfer papers, understanding the printing techniques is paramount. DTF printing entails specific processes, including the application of powder adhesive, which is crucial for ensuring that prints adhere properly to fabrics. Mastering this process can lead to impressive results that resonate well with customers seeking quality. Moreover, print settings—such as temperature, pressure, and timing—must be meticulously calibrated to achieve the best results, making technique comprehension a top priority.

In addition to mastering the basic techniques, experimenting with various techniques and settings can help users discover personalized approaches that yield optimal outputs. This iterative process allows artists and businesses to refine their methods, leading to enhanced print quality over time. By sharing experiences and learning from each other, members of the DTF printing community can continually elevate their craft.

Common Challenges in DTF Transfer Printing

Despite the advantages of DTF transfer printing, several challenges can arise that may hinder the overall experience. Common issues include peeling and color fading, which can result from using inferior quality papers or improper technique. Addressing these challenges often requires collaboration between artists and brands, leading to better results and improved understanding of the process. For instance, switching to a higher-quality DTF transfer paper can significantly reduce peeling issues, enhancing print longevity.

Another common hurdle is the need for meticulous attention to detail in the printing process. Many users encounter inconsistent outcomes due to variations in heat press settings or ink types. This underscores the importance of testing different materials and methods to find the perfect combination that works for your specific printing needs. Continuous learning and adaptation will help mitigate these challenges, enabling artists to achieve consistently high-quality prints.

The Future of DTF Transfer Printing in Custom Projects

As the custom printing market continues to evolve, DTF transfer printing is poised to take center stage, driven by its versatility and ease of use. With technological advancements, the quality and efficiency of DTF transfer papers are likely to improve further, allowing artists and entrepreneurs to explore even more creative avenues. The market’s expansion also signals the emergence of new brands and innovative products that could offer exciting options for users.

Moreover, the rise in demand for unique and personalized products means that DTF transfer printing will remain a key player in meeting customer expectations. As businesses look to differentiate themselves, the ability to produce high-quality, customized items on a wide range of fabrics will be a significant advantage. The future is bright for DTF printing, and those who embrace these advancements will be well-equipped to thrive in a competitive marketplace.

Frequently Asked Questions

What are the best DTF transfer papers for vibrant prints?

When searching for the best DTF transfer papers, consider brands like Hosea, A-SUB, and Siser. These brands are known for producing high-quality transfer papers that deliver vibrant colors and excellent adhesion, suitable for a variety of fabrics.

How does DTF printing work and what are its advantages?

DTF printing involves printing designs onto a special transfer film that is then applied to fabric using heat. This method allows for intricate designs without extensive pre-treatment and is ideal for custom apparel and promotional items, providing durability and high-quality prints.

What factors should I consider when choosing transfer paper for fabric?

When selecting transfer paper for fabric, consider print quality, fabric compatibility (like cotton or polyester), and the type of finish (matte or glossy). These factors significantly affect the vibrancy and longevity of your prints.

How to choose DTF papers that best suit my printing needs?

To choose DTF papers that suit your needs, assess the types of projects you plan to print, the fabric types you will use, and review the specifications like heat settings. It’s also valuable to check user reviews for insights on performance.

Can artists benefit from DTF printing, and how?

Yes, DTF printing offers artists the ability to transfer detailed and vibrant designs onto various fabrics, making it an excellent choice for creating custom apparel and unique art pieces that stand out.

What are common challenges with DTF transfer papers and how can I avoid them?

Common challenges include peeling and color fading, often due to low-quality papers or incorrect settings. To avoid these issues, invest in high-quality DTF transfer papers, use proper heat settings, and ensure you perform test prints.

| Feature | Details |

|---|---|

| Introduction | DTF transfer papers offer vibrant designs for fabrics, ideal for small businesses. |

| Types of DTF Transfer Papers | 1. Cold Peel: Allows for finer finishes. 2. Hot Peel: Quick peeling process, may impact detail. |

| Matte vs. Glossy | Matte: Subdued finish. Glossy: Enhances color vibrancy. |

| Fabric Compatibility | Works with cotton, polyester, and blends. |

| Top Brands | 1. Hosea: Superior adhesion. 2. A-SUB: High-quality prints. 3. Siser: Durable and wash-resistant. 4. Epson: Excellent results with detailed designs. |

| Factors to Consider | 1. Print settings. 2. Durability of inks and powders. 3. Proper storage. |

| Common Challenges | 1. Peeling issues due to improper settings. 2. Color fading with low-quality materials. |

Summary

DTF transfer papers offer a revolutionary means for artists and entrepreneurs looking to create high-quality prints. These innovative papers are designed for vibrant and durable fabric transfers, providing an excellent option for custom printing projects. Understanding the types, brands, and critical factors involved in selecting the right DTF transfer paper is essential for achieving the best results. By utilizing reliable brands such as Hosea, A-SUB, Siser, and Epson, you can ensure your prints not only look stunning but also last. With the proper technique and high-quality materials, DTF transfer papers can significantly elevate your printing game in a competitive market.