DTF transfers on apparel have transformed the way people customize clothing, delivering vibrant color, durable adhesion, and design flexibility that rivals traditional screen printing. If you’re new to this technique, learning how to apply DTF transfers unlocks quick, repeatable results for tees, hoodies, and jackets. DTF transfer designs for clothing can range from bold centerpieces to delicate logos, making it easy to tailor pieces for brands, teams, or personal wardrobes. To help you compare methods, many designers weigh DTF transfers on apparel against DTF vs screen printing, noting the superior color gradients and softer hand feel. And by considering care instructions for DTF transfers and selecting fabrics that respond well, you can maximize the lifespan of DTF transfers on fabric in everyday wear.

For variation, you can think of this as direct-to-film graphics or garment graphics applied with heat, a modern technique that yields bright imagery on clothing. LSI-friendly terms like heat-pressed artwork on fabrics, film-based apparel graphics, and color-rich textures help capture searches around how these visuals are created. In practice, the outcomes resemble traditional screen printing in durability, yet they offer greater flexibility on a wider range of fabrics and garment styles. Understanding care, maintenance, and compatibility—such as recommendations for washing, ironing, and storage—remains essential when integrating these fabric graphics into a collection.

How to apply DTF transfers on apparel: a step-by-step guide

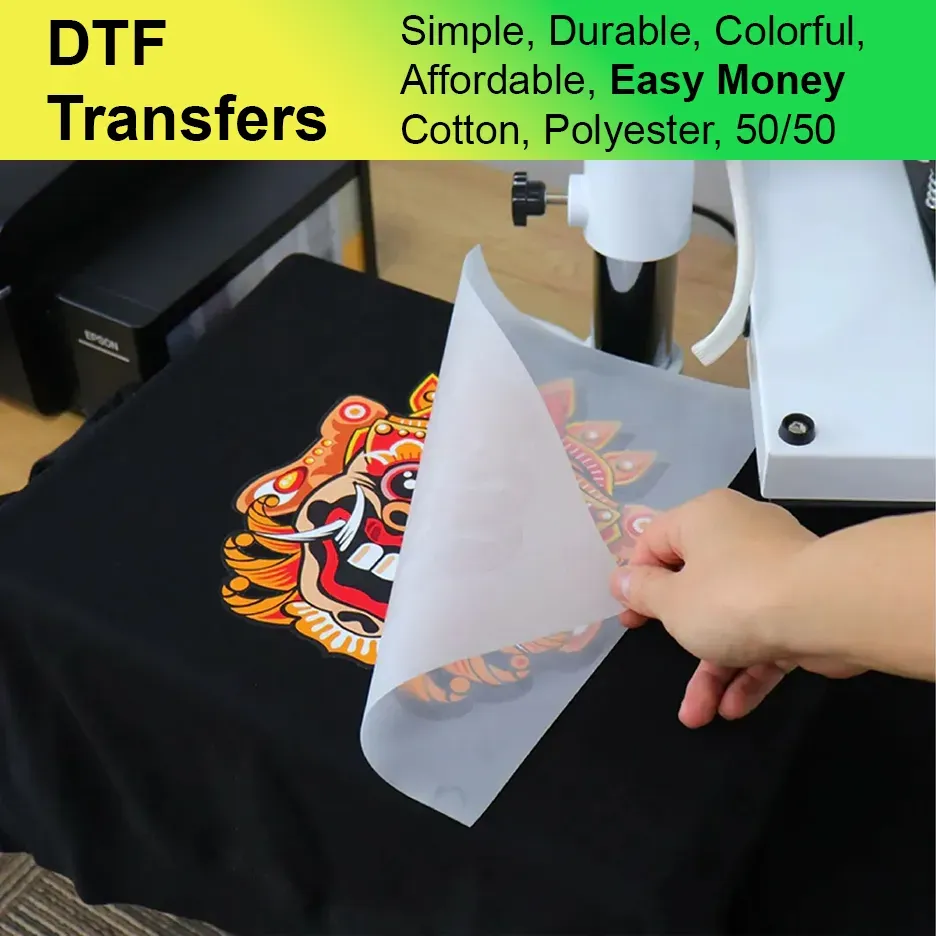

Getting started with DTF transfers on apparel begins with surface preparation, fabric choice, and a clear plan for placement. Understanding how to apply DTF transfers helps you achieve crisp edges and vibrant colors, and it starts with lint-free surfaces, clean fabrics, and proper alignment.

Set your heat press to approximately 305-320°F (150-160°C) with medium to firm pressure for 10-15 seconds. Use a silicone sheet or parchment to protect the transfer and promote even heat distribution. After pressing, allow the garment to cool before peeling to reveal clean edges and optimal adhesion, following the transfer manufacturer’s guidelines for best results with your DTF transfer designs for clothing.

Post-press care and edge checks help maximize durability. Re-press any lifting edges for a few seconds and let the garment cool completely before handling. Keeping a simple log of fabric type, transfer brand, and settings can help you reproduce consistent results across future projects.

DTF transfer designs for clothing: selecting visuals that pop

DTF transfer designs for clothing shine when you consider scale, color contrast, and placement. Bold graphics with high contrast read well from a distance, while gradients and textures benefit from careful layering and tuning.

Choose designs that align with your audience and garment color. Monograms, names, or small logos can complement larger prints without clutter, while full-front artwork demands clear edges and mindful color selection to maintain legibility across sizes.

Test on swatches or similar fabric before committing to final production. Print previews or physical proofs help you gauge edge sharpness, color bloom, and how layers interact on different fabrics.

DTF transfers on fabric: fabric compatibility and texture considerations

DTF transfers on fabric behave differently across fiber types. Cotton and cotton blends typically deliver bright color and strong adhesion, while synthetics may require adjusted heat and dwell times.

For stretch fabrics, verify elasticity by performing a quick bend test and adjust heat or pressure to prevent edge cracking. On very smooth or synthetic blends, lighter designs or smaller motifs can reduce the risk of cracking after laundering.

Nylon, polyester, and performance fabrics may call for different parameters; document outcomes to refine your process across future runs and ensure durable adhesion after multiple washes.

DTF vs screen printing: understanding differences and when to choose

DTF vs screen printing: a quick comparison. DTF shines in full-color fidelity, gradients, and the ability to print complex artwork on demand across varied fabrics without the need for multiple screens.

Screen printing can be more cost-effective for large runs and simple, bold graphics, but lacks some flexibility for on-demand drops or frequent design changes. Consider durability, edge softness, and setup costs when choosing between methods.

For intricate details, small text, or layered designs, DTF often preserves nuance better than traditional screen printing, provided you follow proper curing and fabric compatibility guidelines.

Care instructions for DTF transfers: extend life through washing and storage

Care instructions for DTF transfers: maximize lifespan by washing inside-out in cold water and avoiding harsh chemicals that can degrade adhesives.

Air-dry when possible; if you use a dryer, select a low heat setting and shorter cycles to minimise wear. Avoid ironing directly over the transfer; if ironing is necessary, place a thin cloth or parchment between the iron and the print and press on the garment’s reverse side.

Test care on a small area when trying new fabrics or transfer brands, and avoid chlorine-based bleaches to preserve color integrity and edge durability.

Building a cohesive collection with DTF transfer designs for clothing

Building a cohesive collection with DTF transfer designs for clothing helps create a recognizable line. Start with a core color family or motif that can anchor tees, hoodies, and accessories.

Map out placement across garments—front, back, sleeves, and hems—and maintain consistent scale and spacing to reinforce brand identity. Use recurring elements like a core graphic or monochrome palette to create a harmonious capsule.

Run a small batch of sample pieces across different fabrics to validate color, adhesion, and longevity before a full release. A well-curated set of DTF transfer designs for clothing can boost customer recognition and repeat purchases.

Frequently Asked Questions

How to apply DTF transfers on apparel: what are the essential steps?

To apply DTF transfers on apparel, start with a clean, dry fabric and pre-press to remove moisture. Press at about 305–320°F (150–160°C) with medium to firm pressure for 10–15 seconds, then perform a cold peel (or follow your transfer’s recommended peel method). Use a silicone sheet or parchment to protect the design, and ensure edges are fully adhered. When layering designs, allow each layer to cure briefly before applying the next. After pressing, let the garment cool completely and follow up with gentle care instructions (wash inside-out in cold water).

DTF vs screen printing: how do DTF transfer designs for clothing compare?

DTF transfer designs for clothing deliver vibrant color, fine detail, and compatibility with a wide range of fabrics, making on-demand and small-batch production practical. Compared with screen printing, DTF often offers lower setup costs and easier customization, while screen printing can be more cost-effective for very large runs. Both methods have their place, depending on volume, fabric, and desired feel.

What are care instructions for DTF transfers?

Care instructions for DTF transfers aim to protect adhesion and color: turn garments inside-out before washing, use a gentle cold or warm cycle, and avoid chlorine bleach. Dry on a low heat setting or air-dry when possible. Do not iron directly on the transfer; if ironing is necessary, place a cloth between the iron and the transfer. Following these guidelines helps maximize durability of DTF transfers on apparel.

DTF transfers on fabric: which fabrics work best and what should I know?

DTF transfers on fabric perform well on cotton, polyester blends, denim, and many blends. For very smooth or synthetic fabrics, test adhesion and elasticity, especially on stretch materials. On light-colored fabrics, dark or white bases often improve visibility, while darker fabrics may benefit from lighter transfers. Always verify heat settings and follow manufacturer guidelines for best results on each fabric type.

DTF transfer designs for clothing: what should I consider when choosing designs?

When selecting DTF transfer designs for clothing, consider the garment’s purpose, the audience, and color harmony. Bold graphics work well on tees and hoodies, while team colors and legible logos suit merch and uniforms. Think about scale, contrast, placement (front, back, sleeves), and how gradients or textures will render on fabric to ensure the design remains impactful across washes.

DTF transfers on apparel: how long do they last with proper care?

With proper application and care, DTF transfers on apparel can last through many washes. Ensure correct temperature, time, and pressure during application, allow proper curing, and follow care guidelines (inside-out washing, cold water, low-heat drying). Avoid direct high heat on the transfer and test on a small area if using new fabrics or transfer types to maximize longevity.

| Topic | Key Points |

|---|---|

| What are DTF transfers on apparel? | DTF transfers (direct-to-film) move full-color images from a printable film onto fabric via a heat press. They deliver sharp detail, smooth gradients, and bold color, and are designed for durability when applied correctly. Designs can be layered, offset, or combined with other embellishments, enabling complex artwork. They work on a wide range of fabrics (cotton, polyester blends, denim) and accommodate various garment types. |

| Benefits and capabilities | Vibrant color, durable adhesion, and design flexibility. The method supports layering and multi-design compositions, enabling bold graphics, personalization (names, initials), and logos. Suitable for many fabrics, including cotton, blends, and denim, with strong compatibility across garments. |

| Who can use | Ideal for small-brand entrepreneurs, makers, hobbyists, and anyone who loves personalizing wardrobe staples. Suitable for startups, craft projects, and customized merchandise. |

| Top 10 Creative Ways to Use DTF Transfers on Apparel |

|

| Practical tips for applying DTF transfers on apparel |

|

| Care and longevity of DTF transfers on apparel | DTF transfers are durable but require proper care. Turn garments inside-out before washing; use gentle cycles with cold or warm water. Avoid chlorine bleaches and high-heat dryers; air-drying or low-heat drying extends life. Do not iron directly over transfers; if necessary, place a cloth between iron and transfer or press on the reverse side. Fabric type affects longevity, so test on a small area when using new fabrics. |

| Choosing the right designs for DTF transfers on apparel | Select designs that align with the garment’s purpose and audience. For casual wear, bold, high-contrast graphics work well; for sports, team colors and legibility at distance help. Fashion pieces can use gradients and textures for a premium look. Consider scale, color palette, and garment color to ensure visibility (e.g., light-colored shirts with dark transfers, dark shirts with white or light transfers). Ensure readability and design integrity across sizes. |

| Integrating DTF transfers into a cohesive collection | Develop a core set of designs that share color families or motifs to create consistency. Plan placements (front, back, sleeves, hems) for each piece to build a intentional collection rather than a random assortment. Cohesive branding across drops can improve recognition and encourage repeat purchases. |

| Additional considerations for different fabrics and products | DTF transfers perform well on cotton-based fabrics, blends, and some denims; adjust approach for nylon or poly fabrics. On stretch fabrics, test for elasticity. For light fabrics, ensure visibility; for dark fabrics, use white or light bases to boost contrast. On hoodies/outwear, apply within areas with lower abrasion. Always verify compatibility with the specific fabric and transfer. |

| Conclusion | Conclusion is placeholder in the table and not shown in this summary. |