DIY DTF gangsheets represent an exciting innovation in the realm of custom apparel, streamlining the DTF printing process for enthusiasts and small business owners alike. By utilizing gangsheets, you can print multiple designs on a single transfer film, maximizing efficiency while minimizing material waste. This method not only enhances your productivity but also allows for vibrant, high-quality prints that stand out in the digital printing landscape. As you delve into heat transfer printing, you’ll discover how easy it is to create a variety of custom garments tailored to individual tastes. Embracing DIY DTF gangsheets could be the key to transforming your printing operation into a well-oiled, cost-effective venture, ensuring every design is delivered flawlessly and affordably.

The realm of DIY gang prints, or DTF transfer sheets, is rapidly evolving, offering enthusiastic creators a pathway to effective heat transfer solutions. These innovative sheets allow you to consolidate numerous graphics and designs onto a single film, a technique known as transfer printing. By employing such a method, you’re not just optimizing your workflow; you’re stepping into a world where custom designs can become both a hallmark of your brand and a source of creative expression. With each print job, the potential for vibrant and diverse graphics that appeal to various markets grows exponentially, thanks to the efficiency afforded by this technique. As the demand for personalized apparel surges, mastering digital printing methods like these could set your projects apart from the crowd.

Understanding the Fundamentals of DTF Printing

Direct-to-Film (DTF) printing is revolutionizing the way graphics are transferred onto fabric, making it a favorite among custom apparel creators. The technique enables users to print vibrant and detailed designs directly onto a unique film, which serve as the medium for heat transfer. One of the alluring aspects of DTF printing is its versatility, as it is compatible with multiple fabric types, including cotton, rayon, and synthetics. This allows small businesses and hobbyists alike to cater to a variety of customers and market demands.

The DTF printing process involves several key steps which can enhance overall productivity when done correctly. Beginning with printing on a special film, users subsequently apply an adhesive powder before curing it with heat. This final step is crucial, as achieving a proper bond between the ink, adhesive, and fabric ensures longevity and quality. As such, understanding the fundamentals of DTF printing not only elevates your printing capabilities but also enhances your potential in creating quality custom apparel that stands the test of time.

The Importance of Gangsheets in DTF Printing

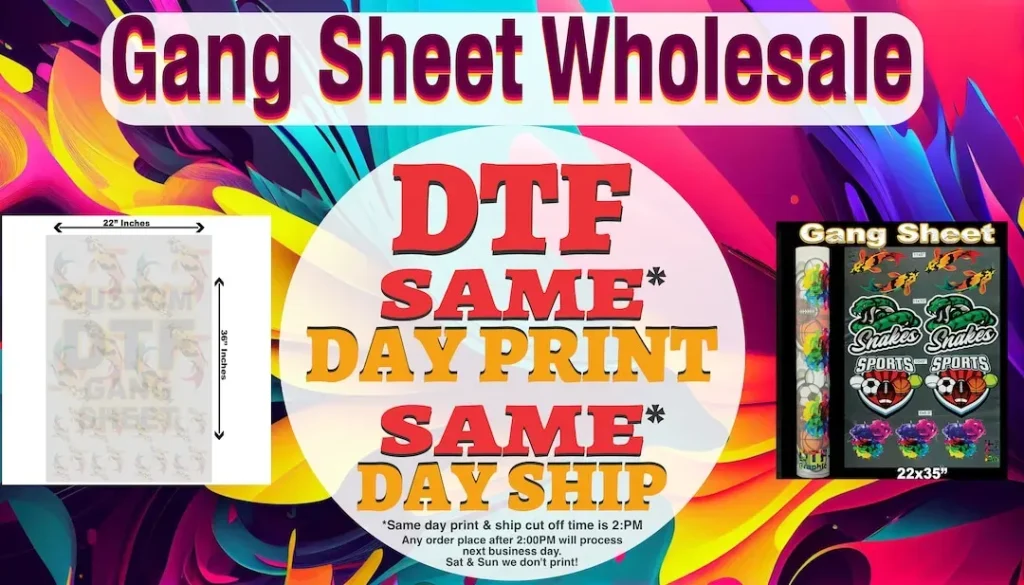

Gangsheets represent a significant advancement in DTF printing, allowing multiple designs to be printed on a single transfer sheet. This not only streamlines the production process but also helps in minimizing material costs by reducing wastage. By using gangsheets, printers can maximize ink usage and efficiently fill the print area, which is especially beneficial when working with diverse designs for a single order.

Furthermore, employing gangsheets enhances productivity in a commercial setting. The ability to transfer several designs at once caters strategically to high-demand orders while saving precious time. Gangsheets are thus vital for anyone looking to refine their workflow and adapt to varied customer needs without the hassle of multiple printing setups, ultimately making DTF printing more cost-effective.

Creating Custom Gangsheets: Best Practices

When it comes to crafting effective DTF gangsheets, using graphic design software is essential. Programs like Adobe Illustrator allow users to create tailored layouts where multiple designs can be arranged aesthetically on the same sheet. Attention to detail in spacing and alignment is paramount; designs should be neither too close to one another nor misaligned, as this can adversely impact the final print quality.

Color management is another crucial aspect of creating successful gangsheets. Printing consistently requires designs to be developed in CMYK color mode to ensure accurate color reproduction. To avoid disappointing surprises during production, running test prints can help in verifying color fidelity and making necessary adjustments. By adhering to these best practices, you will enhance the likelihood of achieving a high-quality finish that aligns with customer expectations.

Gangsheets and Material Efficiency

The utilization of gangsheets in DTF printing dramatically increases material efficiency. Instead of producing one design at a time that could lead to considerable wastage, combining multiple designs on one sheet reduces the amount of film and adhesive used significantly. This not only leads to cost savings but also has a positive environmental impact by minimizing waste associated with printing processes.

Additionally, gangsheets allow for optimized workflow when fulfilling orders of varying sizes. They enable printers to cater to both small batch needs and larger orders without switching constantly between print settings. This operational flexibility can lead to a more streamlined production line, ultimately benefitting businesses by enhancing turnaround times on custom apparel orders.

Enhancing Production Speed with Gangsheets

Utilizing gangsheets can substantially boost production speed in DTF printing operations. By placing multiple designs on a single sheet, printing can be performed in almost half the time it would normally take using a traditional method. This is particularly advantageous for businesses that have to manage bulk orders or seek to keep pace with market trends requiring rapid fulfillment of custom requests.

The quick transition between different designs on a single ink load allows for an effective approach to meeting client demands. As orders come in, printers can prioritize efficiency while maintaining high quality, thus enhancing customer satisfaction and loyalty. By implementing gangsheets, the DTF printing process transforms into a more agile and responsive system that can scale according to order volumes.

Quality Control in DTF Printing and Gangsheets

Quality control is pivotal in the DTF printing process, especially when employing gangsheets. As printers work with multiple designs, maintaining consistency across the prints is essential to uphold brand reputation. Regular checks for defects, such as misprints or incorrect colors, can prevent costly errors and ensure that the final product meets high standards.

Additionally, performing adhesive testing after the printing process is crucial to guarantee durability. This involves applying the prints to fabric and assessing how well they hold up after washing. Implementing a robust quality control system enables businesses to deliver exceptional products while reducing returns and maximizing customer satisfaction.

Frequently Asked Questions

What are DIY DTF gangsheets and how are they used in DTF printing?

DIY DTF gangsheets are sheets of film that contain multiple designs printed simultaneously using DTF printing technology. This method allows for efficient use of materials and reduces waste, making it perfect for custom apparel production by enabling the printing of several designs at once for heat transfer.

How do gangsheets optimize the DTF printing process?

Gangsheets optimize the DTF printing process by allowing multiple designs to be printed on a single film transfer. This reduces material costs and increases production speed, making it ideal for small businesses and DIY projects looking to fulfill various custom apparel orders efficiently.

What are the advantages of using DTF gangsheets for custom apparel?

Using DTF gangsheets for custom apparel offers several advantages: cost-effectiveness from reduced waste, increased production speed by printing multiple designs simultaneously, and added flexibility for creating unique, personalized designs tailored to customer preferences.

Can I create my own designs for DTF gangsheets?

Yes, you can create your own designs for DTF gangsheets using graphic design software like Adobe Illustrator. Proper layout and color management Techniques, such as working in CMYK color mode and ensuring adequate spacing, are vital for producing quality prints.

What steps should I follow to print effective DTF gangsheets?

To print effective DTF gangsheets, first design your layout, manage colors properly, and then print using a DTF printer. Apply adhesive to the printed film, cure it, and perform quality checks to ensure the designs adhere correctly to the fabric.

Where can I learn more about DIY DTF gangsheets and their applications?

You can learn more about DIY DTF gangsheets and their applications from resources like Printavo and Sublimation 101, which provide valuable insights and tips for improving your DTF printing techniques and workflow efficiency.

| Key Points | Description | Details | |

|---|---|---|---|

| What is DTF Printing? | A printing method that transfers designs onto fabric via a special film. | ||

| Understanding Gangsheets | Multiple designs printed on a single transfer sheet, optimizing material usage and lowering costs. | ||

| Benefits of DTF Gangsheets | Cost-effective, increases production speed, and offers greater design flexibility. | ||

| Creating Effective Gangsheets | Proper layout design, color management, printing process, and quality control are crucial. | ||

Summary

DIY DTF Gangsheets are an essential tool for optimizing your workflow in the direct-to-film printing process. By utilizing gangsheets, DIY enthusiasts and small business owners can efficiently produce high-quality designs, enhancing productivity while reducing printing costs. This innovative approach allows for multiple designs to be printed simultaneously, leading to reduced waste and increased customization opportunities, making it particularly appealing for personalized apparel. Mastering the creation of DTF gangsheets not only streamlines production but also caters to a growing market of unique and customized garments. Stay ahead in the printing industry by implementing these strategies and continuously refining your techniques for even better results.