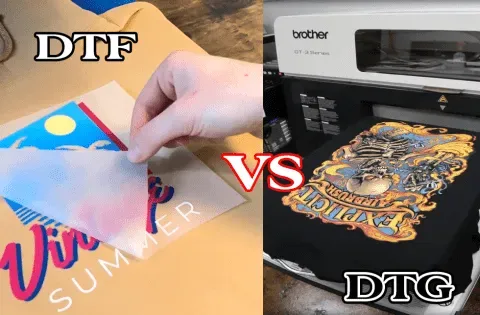

In the competitive realm of textile printing, understanding the differences between DTF vs. DTG is essential for anyone keen on producing high-quality apparel. Direct to Film (DTF) and Direct to Garment (DTG) are two innovative methods that cater to a variety of printing needs, each with its own unique characteristics. While DTF excels in versatility and can handle multiple fabric types, DTG is celebrated for its intricate designs and soft finish on cotton. Exploring these methods not only opens doors to artistic expression but also enhances print durability and fabric compatibility, making it easier to choose the best technique for your project. In this article, we’ll explore the key distinctions, applications, and future trends surrounding DTF and DTG printing to guide your decision-making process.

Textile printing has evolved significantly, with methods like direct film printing and garment printing leading the charge. The terminology surrounding these processes can sometimes be confusing, but grasping the concepts of DTF and DTG can greatly influence your printing decisions. Direct film printing stands out for its adaptability to various materials, making it an attractive option for diverse clothing lines. Conversely, garment printing focuses on delivering exquisite detail primarily for natural fabrics, catering to niche markets that demand high-quality results. By diving into the nuances of these printing styles, you can better navigate their respective strengths and applications, enhancing your overall printing experience.

Understanding DTF Printing Technology

DTF, or Direct to Film printing, represents a groundbreaking approach in the textile printing arena. This process involves printing images onto a transfer film coated with a special adhesive, which is then heat-pressed onto various fabrics. One of the distinguishing features of DTF printing is its ability to produce vivid colors and intricate designs, making it highly sought after in the custom apparel market. Moreover, DTF is not limited to cotton; it can effectively print on polyester, nylon, and blends, making it a versatile solution for diverse fabric types.

Another significant advantage of DTF technology lies in its durability. The adhesion process bonds the ink to the fabric, leading to prints that withstand multiple washes without substantial fading. This longevity appeals to businesses aiming for high quality and reliability in their textile offerings. Additionally, the efficiency of DTF in handling multi-color designs without compromising quality positions it as a favorable choice for those looking to offer expressive and colorful garments.

Exploring DTG Printing Benefits

DTG, or Direct to Garment printing, employs advanced inkjet technology to apply high-quality inks directly onto fabric surfaces. This method excels particularly on 100% cotton materials, resulting in stunningly detailed prints with a soft, breathable feel. Although DTG is ideal for intricate designs that require color precision and vibrancy, it primarily works best with natural fabrics, limiting its wide-scale versatility in textile printing.

One of the remarkable characteristics of DTG printing is its efficiency for small production runs. This capability allows designers and brands to create limited-edition garments with high-definition graphics that resonate with customers. However, it’s noteworthy that while DTG prints achieve exceptional detailing, they may face challenges regarding print durability and color saturation, especially when compared to the resilient qualities of DTF.

DTF vs. DTG: Key Differences in Print Quality

When comparing DTF and DTG printing, one must consider print quality and durability. DTF printing tends to deliver vibrant color output and is highly adaptable to various fabric types, which allows for greater design flexibility. The ability to create bold multi-colored prints without loss of detail is a defining advantage of DTF, especially for designers who prioritize visual impact.

DTG, while known for its exquisite detailing, can sometimes struggle with color vibrancy and depth—particularly on larger pieces. The printing method is tailored more towards natural fabrics, meaning users seeking to print on synthetic or blended textiles may find their options limited. Thus, for businesses that require a wider range of fabric compatibility without sacrificing aesthetic quality, DTF poses significant benefits over traditional DTG methods.

Material Compatibility in Textile Printing

Material compatibility is a vital aspect to consider when choosing between DTF and DTG printing techniques. DTF printing shines in this regard, as it caters to a broader spectrum of fabric materials, including polyester, nylon, cotton, and blends. This versatility enhances DTF’s attractiveness, especially in industries where diverse fabrics are essential for product offerings.

In contrast, DTG printing is predominantly aligned with natural fibers, particularly 100% cotton. While it excels at producing exquisite detail, the lack of compatibility with synthetic materials can restrict its usability for brands wanting to create extensive fabric collections. As a result, those working with varied fabric types may gravitate towards DTF for its expansive capabilities, while DTG remains a strong choice for high-quality cotton-centric products.

Cost Efficiency: DTF vs. DTG

Cost efficiency is a crucial factor when selecting a printing method, especially for businesses aiming to optimize their production expenses. DTF printing typically presents lower setup costs and a quicker production timeline, making it an economical choice for smaller batches and varied designs. The initial investment required is relatively modest in comparison to DTG, which often necessitates higher capital for equipment and maintenance.

Conversely, while DTG printing can deliver exceptional detail and quality, the cost per print may increase with the complexity and size of the designs. This limitation often makes DTG less suitable for larger production runs. Therefore, companies looking for flexibility in costs alongside quality output might find DTF more practical, especially when launching niche or limited-quantity apparel lines.

Future Trends in Textile Printing Technologies

As the textile printing sector continues to evolve, both DTF and DTG technologies are at the forefront of innovation. Recent developments focus on sustainability, with advancements in eco-friendly inks and processes reshaping industry standards. Many companies are now investing in lower environmental impact materials while improving the longevity of prints, responding to increasing consumer demand for sustainable products.

These technological advancements not only improve print durability and quality but also emphasize an eco-conscious approach to textile production. By aligning with sustainability trends, businesses that adopt DTF and DTG printing methods are likely to appeal to a growing demographic of eco-aware consumers, creating new market opportunities while contributing positively to the environment.

Frequently Asked Questions

What are the main differences between DTF vs. DTG printing methods?

The main differences between DTF (Direct to Film) and DTG (Direct to Garment) lie in their printing technology and fabric compatibility. DTF uses a film to transfer designs onto various fabrics, making it versatile for materials like polyester and nylon. In contrast, DTG prints directly onto fabrics using inkjet technology, primarily suited for 100% cotton. Additionally, DTF offers superior print durability compared to DTG, which may fade more easily depending on the ink quality and care.

Which printing method, DTF vs. DTG, is better for fabric compatibility?

DTF printing is more advantageous when considering fabric compatibility since it works well with a wide range of materials, including cotton blends, nylon, and polyester. DTG, on the other hand, excels primarily on 100% cotton fabrics, limiting its application to natural fibers. Therefore, if you need a versatile solution for various fabric types, DTF is the preferred choice.

How does print durability compare in DTF vs. DTG printing?

When it comes to print durability, DTF printing is known for its robust adhesive layer that bonds well with fabrics, ensuring lasting prints even after numerous washes. In comparison, DTG prints, while capable of producing high-resolution designs, often have a lower durability rate and may fade over time, especially if the garment care instructions are not followed. Thus, DTF typically provides better long-term performance.

Is DTF vs. DTG printing more cost-effective for small runs?

For small production runs, DTF printing tends to be more cost-effective due to lower setup costs and a faster printing process. This efficiency allows businesses to create diverse offerings without significant financial risk. Conversely, DTG printing usually requires a larger initial investment and can be less efficient for smaller batches due to slower processing speeds. Therefore, DTF is often the better choice for small-scale operations.

What type of designs are better suited for DTF vs. DTG printing?

DTF printing is particularly effective for complex designs that require vibrant, multi-color outputs and fine details, making it ideal for intricate graphics. DTG printing, while capable of producing stunning and detailed images, may struggle with color saturation in larger runs. Consequently, if your project involves complex artworks, DTF may be the superior option.

What advancements are being made in DTF vs. DTG printing technologies?

Recent advancements in DTF and DTG printing technologies include innovations in ink formulations, particularly regarding eco-friendly options aimed at reducing environmental impact. Both methods are evolving to enhance print quality, durability, and sustainability, with many companies investing in research to optimize the use of these newer inks, which appeals to eco-conscious consumers. This progression ensures that both DTF and DTG continue to adapt to market demands and customer preferences.

| Feature | DTF (Direct to Film) | DTG (Direct to Garment) |

|---|---|---|

| Technology | Heat transfer from a film to fabric, allowing for vivid colors and compatibility with various materials. | Direct inkjet printing onto fabrics, ideal for high-detail results primarily on cotton. |

| Material Compatibility | Versatile, works on nylon, polyester, and cotton blends. | Best for 100% cotton, limiting broader applications. |

| Print Durability | Durable prints that withstand multiple washes without significant fading. | Durability reliant on ink quality and garment care; may fade over time. |

| Cost and Efficiency | More cost-effective for small runs; faster production process. | Higher initial investment; slower speeds for larger runs make it less efficient. |

| Design Complexity | Excels in complex, multi-color prints and fine detail without quality loss. | Better for detailed designs but struggles with color saturation in larger quantities. |

Summary

DTF vs. DTG are two key methods in the textile printing industry, each offering distinct benefits for different applications. DTF, or Direct to Film printing, is a versatile technique known for vibrant colors and compatibility with various fabrics, making it ideal for diverse apparel lines. Conversely, DTG, or Direct to Garment printing, focuses on high-quality, intricate designs specifically for cotton fabrics, valued for its detail and soft finish. The choice between these two methods hinges on factors such as material compatibility, cost, and design requirements, essential for anyone looking to make an informed decision in textile printing.