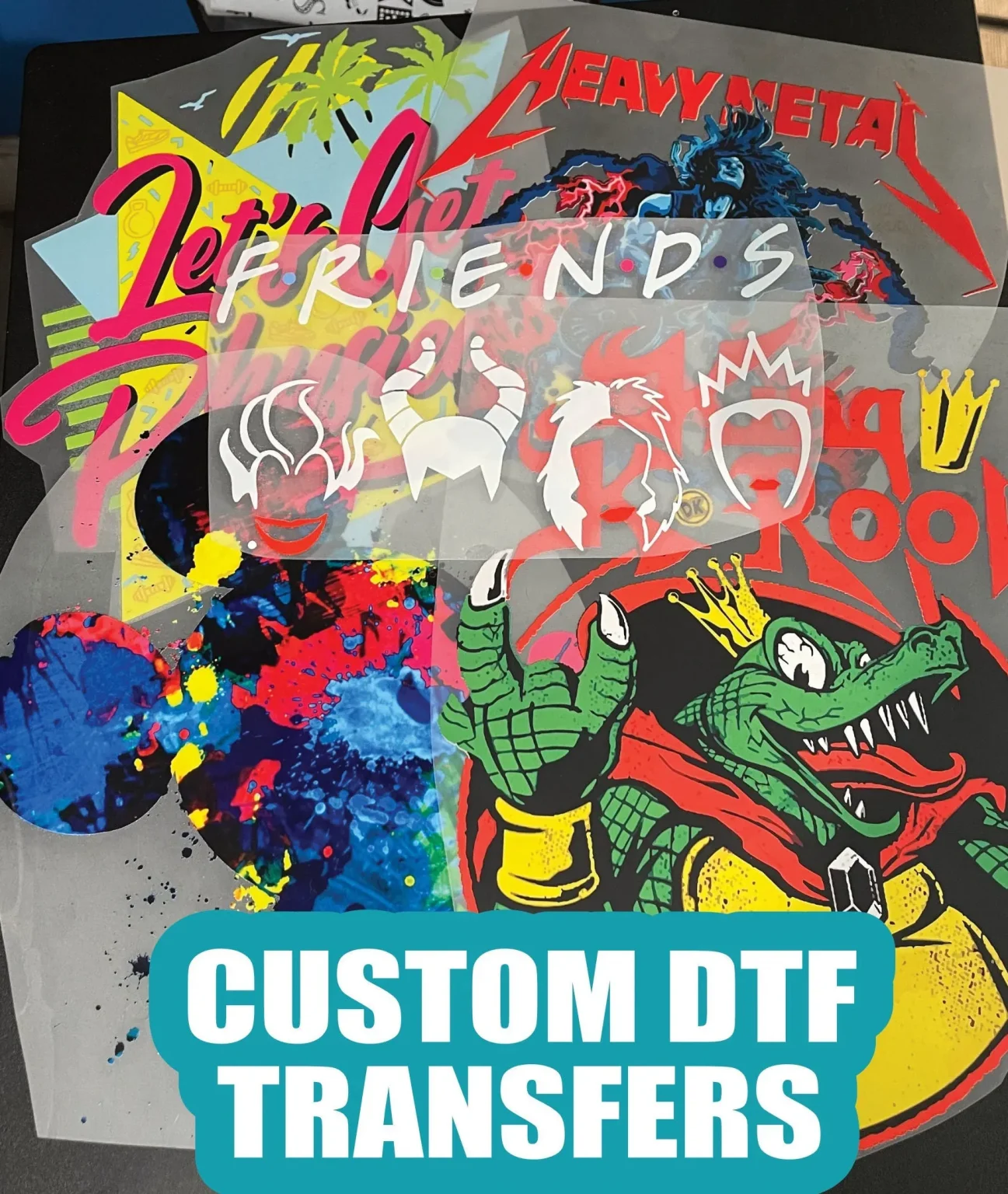

DTF transfers, or Direct-to-Film transfers, are revolutionizing the landscape of apparel printing methods with their cutting-edge technology. This innovative process allows for strikingly vibrant designs to be printed directly onto a special film using advanced DTF printing techniques, making them ideal for various fabric types. As the demand for high-quality, durable prints rises, DTF technology is quickly becoming a preferred choice among businesses in the fashion printing industry. In this blog post, we will delve into the science and benefits of DTF transfers, highlighting their versatility and efficacy compared to traditional methods. Join us as we explore how DTF is transforming apparel printing and meeting the needs of modern consumers.

During the past few years, the adoption of Direct-to-Film technology has made significant strides within the textile industry, offering fresh alternatives in garment decoration. Known for its ability to produce stunning and detailed prints, DTF has rapidly emerged as a popular choice among custom print shops and fashion designers alike. With its efficient and adaptable approach to printing, often referred to as Direct-to-Film application, businesses are finding ways to enhance their offerings without compromising on quality. By utilizing this advanced printing method, brands are now able to cater to diverse demands and embrace the latest trends in fashion. Let’s take a closer look at how DTF transfers are changing the game in apparel printing.

Understanding DTF Printing Technology

DTF printing technology, or Direct-to-Film printing, represents a significant leap forward in the fabrication of vibrant apparel graphics. At its core, DTF employs a specially designed printer that utilizes water-based inks to transfer designs onto a film. This process begins with articulating detailed digital designs that can range from logos to intricate artwork, making it adaptable for various creative needs. After the design is printed onto a transparent film, it is coated with a revolutionary hot-melt adhesive powder which enhances the durability and longevity of the final product.

Unlike other apparel printing methods, DTF technology opens up a plethora of possibilities for fabric types. The film can easily adhere to diverse materials, including cotton, polyester, and blends, ensuring that designers can cater to a wide range of customer preferences. The print’s operational effectiveness and quality make DTF a desirable option for brands looking to innovate and differentiate themselves in an increasingly competitive market.

The Advantages of DTF Transfers

DTF transfers are gaining traction for several compelling reasons within the apparel decoration industry. First and foremost, the durability of DTF prints is impressive; they not only resist the abrasion typically faced in everyday wear but also maintain their striking appearance even after repeated wash cycles. This resilience is combined with a soft tactile feel, avoiding the thick, rigid finishes associated with other printing methods like screen printing. This makes DTF an attractive choice for brands that prioritize both aesthetics and comfort in garment design.

Another significant advantage lies in the operational speed and efficiency of DTF printing. Businesses can achieve quick turnaround times, responding rapidly to customer demands for unique and custom designs. The ability to produce short runs without compromising quality positions DTF as an ideal solution for small businesses and startups wanting to provide customized merchandise, showcasing the technology’s versatility in various market segments.

The High-Quality Output of DTF Technology

A distinctive characteristic of DTF technology is its capability of delivering high-definition prints with remarkable vibrancy and detail. The advanced ink formulations optimize color saturation and adhesion, resulting in images that pop on fabric with brilliant accuracy. Businesses leveraging DTF can create intricate designs that often surpass those produced with traditional printing techniques, thus meeting the demands of discerning customers who crave customized apparel.

Furthermore, DTF’s adaptability means it can accommodate an array of design complexities which can be a game-changer for brands looking to make a statement. The quality of output not only enhances the appeal of the apparel but also helps to foster customer loyalty, as consumers recognize the value that comes with high-quality, visually striking products.

Recent Innovations in DTF Printing

The DTF printing landscape is undergoing rapid transformation, driven by innovative advancements in both printer technology and ink formulation. Recently, manufacturers have introduced high-speed DTF printers capable of producing superior prints and enhancing operational efficiency. These new models incorporate cutting-edge heating and adhesive systems that not only improve print quality but also reduce overall production costs.

Additionally, the focus on eco-friendly ink options in DTF printing represents a significant shift towards sustainability within the industry. As environmental awareness spreads, consumers and companies alike are driving demand for greener printing solutions, making these innovations invaluable. The integration of eco-conscious practices not only caters to customer preferences but also helps businesses position themselves as responsible operators in a competitive marketplace.

The Rising Popularity of DTF Transfers

Across the printing industry, there is an undeniable trend towards the adoption of DTF transfers. Print shops, clothing manufacturers, and creative entrepreneurs are recognizing the high-quality output, efficiency, and versatility that DTF offers. As businesses increasingly pivot to this technology, they find it enables them to meet customer requests for one-of-a-kind apparel with ease, propelling DTF printing into broader acceptance.

The growing popularity is also attributed to DTF’s ability to balance production demands alongside the need for unique, custom prints. As customer expectations evolve, companies that embrace DTF technology position themselves to thrive, tapping into the unique opportunities this innovative printing method presents. It is anticipated that as education around DTF expands, we will see an even greater escalation in its industry adoption.

DTF vs. Traditional Printing Methods

When comparing DTF transfers to traditional printing methods, the advantages of DTF become quite evident. Traditional techniques like screen printing often involve complex setups and are limited in terms of design flexibility, especially for small volume runs. DTF, on the other hand, simplifies the overall workflow, allowing for rich, detailed prints that can be achieved quickly, thereby reducing downtime for businesses.

Moreover, the cost-effectiveness of DTF compared to conventional approaches is significant. With lower initial investment and reduced waste, DTF allows smaller ventures the opportunity to offer diverse printing services without the financial burden associated with traditional setups. This inclusivity opens doors for new entrants into the apparel market, promoting innovation and creativity.

Frequently Asked Questions

What is DTF transfer technology and how does it work?

DTF transfer technology, or Direct-to-Film printing, involves printing designs on a special film using water-based inks. After printing, the film is coated with a hot-melt adhesive and then heat pressed onto garments, allowing for vibrant and durable prints on various fabrics.

What are the benefits of using DTF transfers for apparel printing?

DTF transfers offer numerous benefits including superior durability, flexibility across different fabric types, high print detail and vibrancy, faster production times, and cost-effectiveness, making it an ideal choice for small businesses and custom print shops.

How does DTF printing compare to traditional printing methods?

Compared to traditional methods like screen printing, DTF printing provides better adhesion, softer prints, and longer-lasting designs. It allows for quick production of intricate designs with vibrant colors, while also being more suitable for short runs and customization.

Is DTF technology suitable for all fabric types?

Yes, DTF technology is versatile and can be used on various fabric types, including cotton, polyester, and blends. This makes it an excellent choice for diverse apparel printing needs and applications.

What advancements are being made in DTF transfer technology?

Recent advancements in DTF technology include faster and more efficient printers, improved heating systems, eco-friendly ink formulations, and enhanced adhesive systems, all contributing to higher quality and more sustainable printing solutions.

Why is DTF printing gaining popularity in the custom apparel industry?

DTF printing is gaining popularity due to its ability to produce high-quality, customized prints efficiently and cost-effectively. The technology meets the growing demand for unique designs and is accessible for both small businesses and larger manufacturers.

| Key Aspects | Details |

|---|---|

| What is DTF Transfer Technology? | Printing designs onto a special film with advanced water-based inks. Produces vibrant images for various fabrics after applying hot-melt adhesive powder. |

| The Process of DTF Printing | 1. Design Creation 2. Printing onto film 3. Powder Adhesive Application 4. Heat Transfer onto garment |

| Benefits of DTF Transfers | 1. Durability and Flexibility 2. Speed and Efficiency 3. High Detail and Vibrancy 4. Cost-Effectiveness |

| Recent Developments in DTF Technology | 1. Faster and more efficient printers 2. Innovations in ink technology for eco-friendliness |

| Industry Adoption of DTF Transfers | Growing use among custom print shops, manufacturers and hobbyists. Offers detailed designs with minimal waste, leading to satisfied customers. |

Summary

DTF Transfers are transforming the custom printing landscape by offering a technology that combines excellence and efficiency. The innovative process enables businesses to create vibrant, durable designs that resonate with diverse fabric types, making it a versatile choice for custom printed apparel. As the demand for high-quality, customized products increases, DTF transfers stand at the forefront, providing a cost-effective solution for both small startups and larger manufacturers. With technological advancements ensuring ongoing improvements, the future of DTF transfers seems bright, promising to reshape how we think about printing in the textile industry.