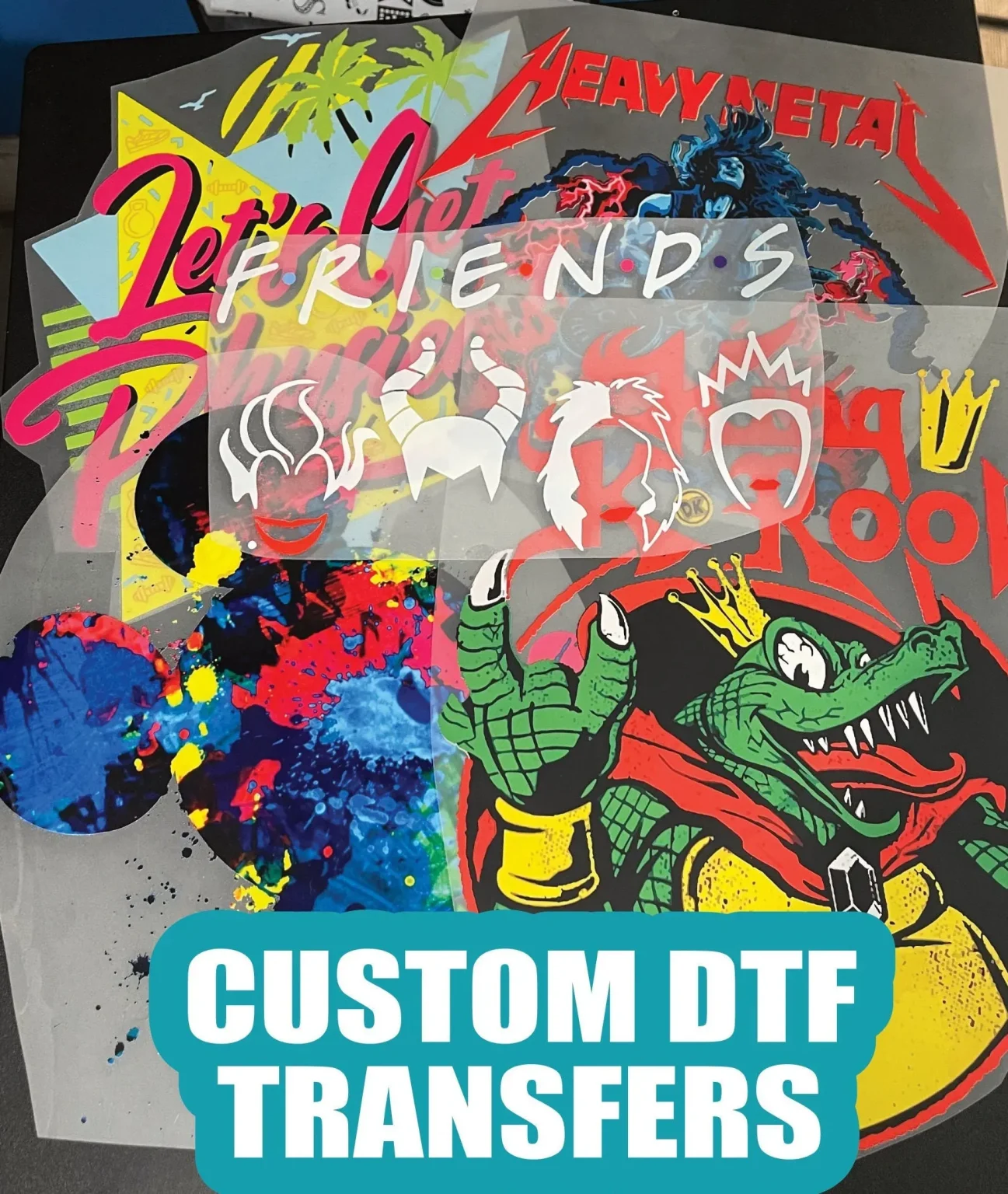

In the rapidly evolving world of custom apparel, DTF transfers stand out as a revolutionary printing method that allows creators to unlock their artistic potential. Direct-to-Film (DTF) transfer printing is changing the landscape of garment decoration, offering high-quality, vibrant prints that adhere beautifully to various fabric types. This innovative technique is ideal for beginners looking to dive into custom apparel printing, as it combines ease of use with impressive results. In this guide, we will share essential DTF transfer tips to help you navigate the intricacies of this exciting field. Whether you’re just starting or seeking to refine your skills, understanding DTF printing techniques will be invaluable to your creative journey.

When exploring the world of garment decoration, one might encounter terms like film transfers and heat transfer printing, both of which embody similar principles to DTF transfers. This novel approach to custom printing simplifies the process of applying intricate designs to fabrics without compromising quality. As beginners dive into this method, the importance of mastering various DTF printing techniques becomes evident, ensuring the creation of stunning, resilient products. Utilizing advanced technology and high-quality materials, film transfer methods enable hobbyists and businesses alike to produce professional-grade attire. With a solid understanding of these alternative terms and the techniques behind them, aspiring printers can more confidently tackle their custom apparel projects.

Understanding DTF Printing Technology

Direct-to-Film (DTF) printing technology is revolutionizing the custom apparel industry by offering an innovative solution for high-quality prints. Unlike traditional screen printing or heat transfer methods, DTF printing involves printing designs on a special film that is then transferred onto the fabric using heat and pressure. This technology allows for vibrant colors and detailed designs that can cater to a wide array of fabric types, including cotton and polyester. As such, understanding the mechanics of DTF printing is paramount for anyone looking to venture into this exciting field.

Moreover, DTF printing not only produces eye-catching results but also promises durability, making it a preferred choice for both beginners and seasoned professionals. Knowing how to properly utilize this technology can set you apart in a crowded market. Beginners should take the time to research various DTF printing techniques and familiarize themselves with the equipment needed to get started, thus laying a strong foundation for their custom apparel business.

Essential Equipment for DTF Transfers

The success of your DTF transfer journey largely depends on the equipment you choose. It’s vital to invest in a compatible printer—most professionals recommend Epson printers modified specifically for DTF applications due to their high-resolution output and reliability. Additionally, high-quality heat presses are essential for ensuring that your transfers adhere properly to the fabric. Researching various models and their specifications is a crucial step for beginners wanting to make informed purchasing decisions.

Furthermore, don’t overlook the significance of selecting appropriate inks and films. The vibrancy of your prints can be severely affected by the quality of the materials used. Therefore, aim to source high-quality DTF inks and films from reputable suppliers. Testing various options will allow you to find the best combinations that bring out the best in your prints. With the right equipment in hand, you’ll be better equipped to tackle any DTF transfer project with confidence.

Choosing Quality Inks and Films

When it comes to DTF transfers, quality is paramount. The inks and transfer films you choose directly impact the final product’s durability and vibrancy. Using high-quality DTF inks ensures that the colors remain vibrant and do not fade with regular washing, which is particularly important for custom apparel. Additionally, the films used in the DTF process must have excellent adhesive properties to maintain a strong bond with the fabric.

To achieve stunning results, beginners should take the time to research different brands and types of DTF inks and films to find those that work best for their specific printing style and fabric choices. Consider reaching out to supplier representatives or joining forums where fellow DTF enthusiasts discuss their experiences. In doing so, you’ll be equipped with valuable insights that can guide you in making the best decisions for your custom apparel projects.

Pre-Treatment Processes for Optimal Results

Pre-treating your fabrics is a crucial step that can significantly enhance the quality of your DTF transfers. Proper preparation of the fabric ensures that the designs adhere well and maintain their vibrancy over time. Fabrics like cotton and polyester are particularly ideal for DTF transfers, but applying a pre-treatment can improve the overall adhesion and longevity of the prints.

Before beginning the transfer process, it is advisable to follow the manufacturer’s guidelines for pre-treatment. Skipping this essential step may lead to disappointing results, such as peeling or fading after washing. As a beginner, take the time to experiment with pre-treatment methods to determine which works best for your fabric and printing techniques, ensuring professional-quality results.

Optimizing Print Settings for Success

Optimizing your print settings is vital for achieving the best results with DTF transfers. Every printer has different settings, and adjusting these can significantly affect the detail and color quality of your prints. As a beginner, you’ll want to familiarize yourself with your printer’s capabilities and settings for DTF printing. Key parameters to focus on include resolution, color profiles, and DPI (dots per inch) settings.

Experimentation is essential—try different settings to see what yields the optimal results for your designs. Keep track of your successful configurations to build a reference guide that can assist you in future projects. This approach not only streamlines your workflow but also empowers you to create consistently impressive prints.

Heat Press Techniques for Effective Transfers

Mastering the heat press technique is essential for ensuring your DTF transfers are applied correctly and with durability. The right temperature, time, and pressure settings must be maintained throughout the application process to achieve the desired results. Beginners often experiment with various settings to establish the optimal combination for different types of fabrics.

Before pressing your final products, it’s a good practice to test your settings on scrap fabric. This step will help you refine your technique and avoid damaging the actual garments. By becoming proficient with heat press techniques, you’ll ensure that every DTF transfer is well-executed, leading to successful and impressive custom apparel outcomes.

Frequently Asked Questions

What are DTF transfers and how do they work?

DTF transfers, or Direct-to-Film transfers, involve printing designs onto a special film which is then applied to fabric using heat and pressure. This method is favored in custom apparel printing for its ability to create vibrant, durable prints on various materials like cotton and polyester.

What are some essential DTF transfer tips for beginners?

Beginners in DTF transfers should focus on selecting quality equipment, such as Epson printers compatible with DTF inks. It’s also vital to use high-quality inks and films, pre-treat fabrics for better adhesion, optimize print settings for clarity, perfect heat press techniques, and provide customers with proper care instructions to ensure print longevity.

How can I choose the right printer for DTF printing?

When choosing a printer for DTF printing, select an Epson model that is well-reviewed and compatible with DTF inks. Look for high-resolution capabilities to ensure detailed prints, which are essential for successful custom apparel applications.

What are some common mistakes to avoid in DTF printing techniques?

Common mistakes in DTF printing include using low-quality inks and films, neglecting fabric pre-treatment, and improperly adjusting print settings. Beginners should avoid these pitfalls by investing in quality materials and thoroughly testing their printer settings before final production.

How can I ensure the quality of my DTF transfers?

To ensure the quality of DTF transfers, use high-quality inks, films, and fabrics. Additionally, optimize print settings and test application techniques on scrap fabric before finalizing products. Continuous experimentation will help you fine-tune your DTF process for better results.

What care instructions should I provide for garments with DTF prints?

For garments with DTF prints, advise customers to machine wash in cold water, avoid harsh detergents, and tumble dry on low heat. Providing clear care instruction tags can help prolong the vibrancy and life of the DTF prints.

| Key Point | Description |

|---|---|

| Introduction | Introduces DTF transfers as an innovative technique for custom apparel. |

| Importance of DTF Transfers | DTF transfers are favored for their versatility and ease of use in the custom apparel market. |

| Selecting the Right Equipment | Choosing compatible printers, like modified Epson models, is crucial for high-quality results. |

| Quality Inks and Films | Using high-quality inks and films directly affects print vibrancy and durability. |

| Pre-Treatment of Fabrics | Prepping fabrics improves adhesion of DTF transfers. |

| Optimizing Print Settings | Adjusting printer settings for resolution and color profile enhances print quality. |

| Perfecting Heat Press Techniques | Consistent temperature and pressure are vital for successful transfer application. |

| Educating Customers on Care Instructions | Clear care instructions help maintain print quality and customer satisfaction. |

Summary

DTF Transfers are a revolutionary step in the world of custom apparel, offering exceptional quality and versatility for both beginners and experienced designers. By focusing on the right equipment, high-quality materials, and mastering essential printing techniques, anyone can create vibrant and durable garments that meet customer demands. The journey to mastering DTF transfers is a blend of learning, experimentation, and creativity, empowering you to enhance your offerings with stunning designs. As you embrace this innovative printing method and continuously educate yourself on best practices, you’ll set yourself apart in the competitive market of custom apparel.