When considering DTF vs. DTG vs. Screen Printing, it’s essential to understand how these distinct custom printing methods can impact your business. Each technique—Direct to Film (DTF), Direct to Garment (DTG), and screen printing—offers unique advantages tailored to different printing needs. For instance, DTF printing has surged in popularity for its vibrant output and versatility across various fabrics, while DTG printing excels in detail and personalization for small batches. Meanwhile, traditional screen printing remains a dominant choice for large-volume orders due to its cost-effectiveness and durability. In this guide, we will explore the features, benefits, and potential drawbacks of each printing technology to help you make an informed decision for your custom printing endeavors.

When exploring the landscape of custom printing options, you have a trio of popular methods to consider: Direct to Film (DTF), Direct to Garment (DTG), and traditional screen printing. Each of these printing technologies presents its own set of characteristics that cater to varying production demands and design complexities. DTF printing, often celebrated for its adaptability and vibrant color reproduction, allows businesses to experiment with diverse material types, while DTG printing is highly regarded for delivering intricate designs directly onto garments. Screen printing, a time-tested method, continues to shine for large runs, combining speed with impressive durability. Understanding these alternative techniques is crucial for selecting the most suitable method for your printing projects.

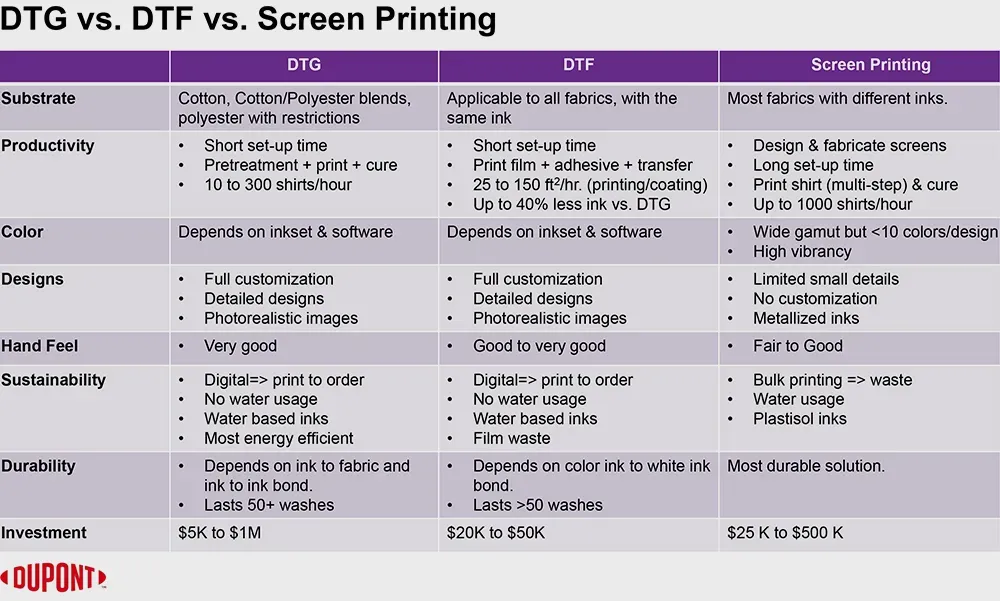

Comparing DTF, DTG, and Screen Printing: An Overview

In the realm of custom printing, understanding the differences between DTF (Direct to Film), DTG (Direct to Garment), and screen printing is paramount for businesses exploring their options. DTF printing is a recent innovation that merges film technology with heat transfer, making it not only versatile across different fabric types but also capable of producing vibrant colors and intricate designs. DTG, on the other hand, uses specialized inkjet technology to print directly onto garments, making it ideal for detailed artwork and smaller quantities. Screen printing, a time-tested technique, remains popular for its efficiency and durability, especially when producing larger batches. Each of these methods caters to different business models and customer needs, thus understanding their nuances enables informed decision-making.

By evaluating the strengths and weaknesses inherent in DTF, DTG, and screen printing, businesses can better align their printing choices with market demands. DTF offers a unique advantage by accommodating a wide range of materials, such as cotton and synthetic fabrics. Conversely, screen printing excels in high-volume production with remarkable durability. In contrast, DTG printing allows for customization with minimal setup costs, making it a cost-effective solution for personalized products. With each method having distinct capabilities, businesses are equipped to tailor their approach based on their specific needs.

For companies looking to carve a niche in the custom printing market, understanding the operational demands of each printing method is essential. DTF printing has disrupted traditional methods by providing an effective solution for smaller runs without compromising on quality. This technology ensures high fidelity in printing, allowing for complex designs to come to life on various textiles. However, the initial investment required for DTF equipment can deter some businesses, particularly start-ups.

On the other side, DTG printing stands out for its ability to handle detailed artwork with ease, catering well to businesses focused on bespoke designs. Despite its versatility, DTG’s reliance on 100% cotton fabric can limit its applicability on other materials, making it critical for businesses to analyze their fabric choices. Meanwhile, screen printing shines as the method of choice for larger orders due to its cost-effectiveness and speed, cementing its place as a staple in the custom printing industry.

Advantages and Disadvantages of DTF Printing

DTF printing has swiftly emerged as a frontrunner among custom printing methods, boasting several advantages that make it appealing to many businesses. First and foremost is its versatility; DTF technology allows for printing on a variety of materials, including cotton, polyester, and blends, opening doors for businesses that work with different fabric types. This ability to cater to diverse market demands is particularly important in today’s rapidly changing consumer landscape. Furthermore, DTF prints integrate bright colors and detailed graphics, making them perfect for intricate designs that attract attention in a crowded marketplace.

However, it’s worth noting that while DTF offers remarkable benefits, it has certain drawbacks as well. One of the primary challenges is the initial investment; the equipment required for DTF printing can be costly, which might deter small business owners or startups from embracing this technology. Additionally, the quality of prints is reliant on good pre-treatment processes and quality film. Without these, the vibrancy and longevity of the prints may be compromised, which can impact customer satisfaction.

In addition to high-quality outputs, DTF printing enables quick turnarounds, making it a suitable option for businesses that require on-demand printing solutions. This responsiveness aligns with trending consumer preferences for personalized and unique items. As customization grows in popularity across various sectors, businesses leveraging DTF can meet customer expectations for timely delivery without sacrificing quality. Thus, the flexibility to handle small orders efficiently is another compelling reason for businesses to consider DTF as a primary printing method.

Despite its potential, one must also consider the necessity for consistent maintenance and careful handling of the DTF equipment to ensure optimal performance. Training staff to properly manage the process adds another layer of complexity for businesses adopting this method. Therefore, weighing the benefits and drawbacks of DTF printing is crucial for those evaluating their options in the competitive custom printing landscape.

Exploring the Benefits of DTG Printing

Direct to Garment (DTG) printing has gained significant traction within the custom printing industry due to its ability to produce high-quality, intricate designs with relative ease. One of the standout advantages of DTG printing is the fantastic detail it can achieve, making it ideal for businesses specializing in custom artwork. From vibrant color gradients to complex imagery, DTG technology uses specialized inkjet systems that allow for striking results akin to digital photography. With no minimum quantity requirements, businesses are empowered to fulfill individual orders while maintaining quality, catering to a growing demand for personalized products.

The simplicity of the DTG printing process is another compelling feature. Unlike traditional methods that require extensive setups, DTG is straightforward, allowing businesses to quickly pivot and adjust to changes in customer demand. This adaptability means businesses can offer a wider array of products, appealing to a more extensive audience without the constraints of bulk orders. The easy integration of DTG printing into workflows supports companies looking to adopt sustainable practices by reducing waste associated with excess inventory.

Nevertheless, while DTG excels in customization and detail, it also comes with certain limitations. Primarily, the DTG printing process is slower in comparison to other methods, like screen printing, which may affect turnaround times for larger orders. Ideal results are often achieved on cotton fabrics, meaning businesses that focus on synthetic materials or blends might face inconsistencies in print quality. Furthermore, as newer printing technologies continue to emerge, keeping pace with advancements is essential for businesses to ensure they do not fall behind competitors that are continuously upgrading their printing capabilities.

Despite these challenges, many businesses are finding that the advantages of DTG printing align closely with modern consumer expectations for personalized options. As customer preferences evolve, DTG can provide a competitive edge in a marketplace increasingly defined by customization and unique offerings. Striking the right balance between quality, efficiency, and adaptability positions DTG as an essential component in the toolkit of custom printing enterprises.

Screen Printing: A Time-Tested Method for Bulk Production

Screen printing has long been recognized for its robust application in bulk production, making it a preferred choice among businesses requiring large volumes of printed items. One of the key advantages of screen printing is the cost-effectiveness it offers for high-volume orders. As the production scale increases, the cost per item decreases significantly, allowing businesses to maximize profit margins. This method also provides unmatched durability; prints created through screen printing are known to resist fading and wear, making them ideal for apparel that undergoes frequent washing and use.

In addition to cost-effectiveness, screen printing allows for vibrant and rich colors due to the thickness of the inks used. This capability enables stunning visual outputs that stand out compared to other printing methods. In many instances, skilled screen printers can also create custom shades by mixing inks, thus expanding the aesthetic possibilities for businesses looking to offer unique designs tailored to customer preferences.

Yet, screen printing does come with its own set of limitations that businesses must take into account. One major drawback is the higher initial setup costs, as creating a screen for each design can be time-consuming and labor-intensive. This aspect makes screen printing less viable for small runs or orders with multiple designs. The method’s inefficiency in handling intricate designs with fine detail may also pose challenges. Although capable of producing high-quality results, screen printing may struggle with designs that have extensive color gradients or elaborate patterns when compared to DTF or DTG methods.

As businesses continue to evaluate their printing options, it’s crucial to recognize both the strengths and weaknesses of screen printing. Despite the emergence of newer technologies like DTF and DTG, screen printing continues to hold its ground, particularly for businesses focusing on large production quantities. Understanding how screen printing fits within diverse business strategies enables companies to harness its benefits while managing its limitations effectively.

Choosing the Best Printing Method for Your Business

Selecting the optimal printing technique for a custom printing business requires careful consideration of several factors, including production needs, order volume, and design complexity. For businesses anticipating low to moderate demand, DTF and DTG may be a perfect match, providing flexibility and customization options without the burden of extensive setup times. By opting for these methods, businesses can cater to individual customer needs and create a unique product line that appeals directly to consumer preferences in today’s market.

In contrast, businesses with large-scale operations may find screen printing to be a more effective solution. With its speed and cost-efficiency for high volume runs, screen printing positions itself as the ideal method for companies focused on maximizing output while keeping production costs in check. Understanding projected order volume before making a decision can help ensure that the selected printing technology aligns with your business goals and operational capabilities.

Additionally, it’s important to analyze the types of designs your business will produce, as different printing methods excel in handling various complexities. DTF and DTG printing shine in their ability to create intricate designs with multiple colors, which is crucial for brands wanting to make a statement with their visual identity. Conversely, while screen printing is incredibly durable and efficient, it may not be as versatile for designs requiring fine detail. Taking the time to evaluate your design specifications alongside your target market’s preferences can significantly influence your choice of printing technology.

Frequently Asked Questions

What is the difference between DTF printing and DTG printing?

DTF (Direct to Film) printing involves transferring designs from a special film to fabric using heat, while DTG (Direct to Garment) printing uses inkjet technology to print directly onto the garment. DTF is known for its versatility across various materials, whereas DTG excels in detailed artwork on predominantly cotton fabrics.

When should I choose DTF printing over screen printing?

Choose DTF printing over screen printing when you need vibrant prints on a variety of materials, especially for small runs or custom orders. DTF is generally more cost-effective for on-demand printing, making it ideal for businesses focusing on personalization.

Is DTG printing suitable for bulk orders compared to screen printing?

DTG printing is not as efficient for bulk orders as screen printing, because it typically has slower production speeds. While DTG is excellent for detailed designs in small quantities, screen printing is more cost-effective and faster for large volume orders.

What are the limitations of screen printing compared to DTF and DTG printing?

Screen printing has higher initial setup costs and is less efficient for small orders or complex designs due to its labor-intensive process. In contrast, DTF and DTG provide greater flexibility for unique customization and intricate artwork.

Can DTF printing be used on different fabric types?

Yes, DTF printing is versatile and works well on various fabrics, including cotton, polyester, and blends. This flexibility makes DTF an attractive choice for businesses that aim to print on multiple fabric types.

What are the costs associated with DTF vs. DTG vs. screen printing?

DTF printing generally requires a substantial initial investment in equipment but is cost-effective for small runs. DTG has low setup costs for individual prints but can be slower, while screen printing is most cost-effective for large volumes, despite higher initial setup costs.

| Printing Method | Advantages | Disadvantages |

|---|---|---|

| DTF (Direct to Film) | – Versatile across materials – Produces vibrant colors – Cost-effective for small runs |

– High initial investment – Quality depends on film and pretreatment |

| DTG (Direct to Garment) | – Excellent for detailed artwork – No setup costs for individual prints – Efficient for small batches |

– Slower than screen printing – Best on 100% cotton |

| Screen Printing | – Cost-effective for large orders – Produces vibrant, durable prints – Faster for bulk production |

– High initial setup costs – Less efficient for small orders and complex designs |

Summary

DTF vs DTG vs Screen Printing are three distinct printing methods crucial for custom printing businesses. Each method has its strengths and weaknesses, making them suitable for varying production needs and designs. DTF shines with its versatility and vibrant quality across many materials, while DTG excels at intricate detail for small batches. On the other hand, screen printing remains the most efficient choice for high-volume orders due to its cost-effectiveness and durability. Ultimately, your choice among these printing techniques should align with your business goals, production volume, and design complexity.