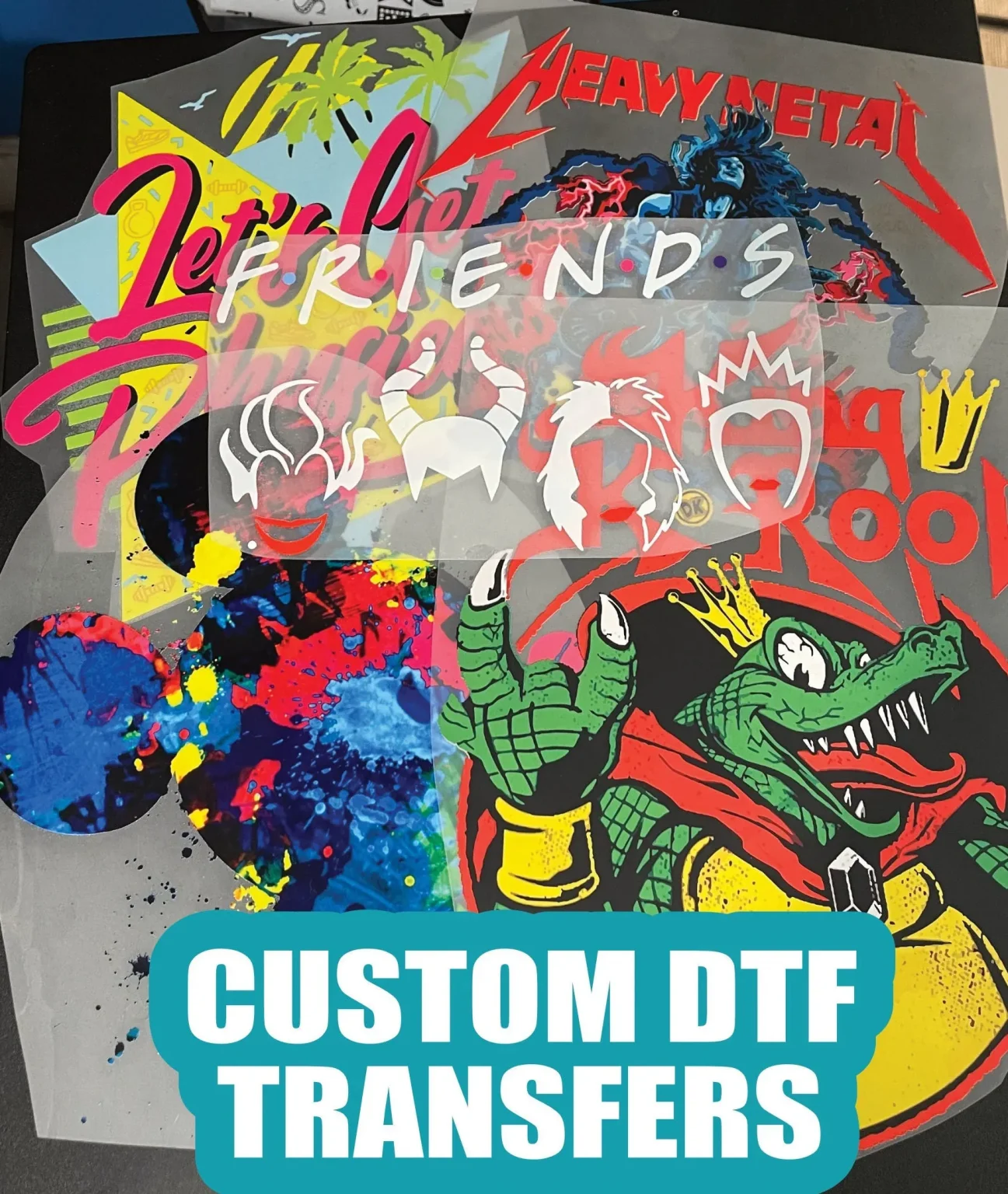

DTF transfers, or Direct-to-Film transfers, are rapidly transforming the landscape of textile printing technology, providing a powerful alternative to traditional garment printing methods. This innovative approach allows for exceptional quality and vivid designs on various fabric types, making DTF printing advantages clear to businesses looking to expand their product offerings. By utilizing eco-friendly DTF options, companies can appeal to the environmentally conscious consumer while maintaining cost efficiency and durability in their prints. Additionally, the simplicity of the DTF process makes it accessible for newcomers and experienced printers alike, encouraging creativity and flexibility in design. In this blog post, we will delve deeper into how DTF transfers are revolutionizing the garment printing industry and the multitude of benefits they present.

Direct-to-Film transfer technology represents a landmark evolution in garment decoration—allowing businesses to create striking prints with ease and efficiency. This method of printing directly onto a specialized film before transferring onto fabric has gained immense popularity for its ability to maintain vibrant colors and impressive detail. As this textile printing method continues to rise in prominence, it highlights the growing trend of innovative printing techniques that prioritize environmental sustainability and cost-effectiveness. The simplicity and versatility of DTF printing offer enhanced opportunities for customization in today’s fast-paced fashion market. By exploring the applications and benefits of this advanced printing technology, we can better understand its vital role in the future of the apparel industry.

Exploring the Benefits of DTF Printing Technology

Direct-to-Film (DTF) printing brings a plethora of benefits that are transforming the textile printing landscape. One of the primary advantages is the capability to produce vibrant, intricate designs that capture the attention of consumers. This technology utilizes specialized inks and advanced printing processes to achieve pictures and patterns that are not only visually appealing but also durable. Designers can experiment with different colors and gradients without the fear of compromising on quality or style, leading to unique and standout garments.

Furthermore, DTF printing is celebrated for its ability to print on a wide range of fabric types, which includes cotton, polyester, blends, and even other synthetic materials. This adaptability allows businesses to cater to various market preferences without investing in multiple printing technologies. As a result, companies can keep pace with fashion trends and consumer demands while maintaining efficiency and quality in their production.

The Eco-Friendly Advantages of DTF Transfers

In the face of growing environmental awareness, DTF transfers have emerged as a more sustainable option within the garment printing industry. Unlike traditional printing methods that often rely heavily on water and harsh chemicals, DTF technology can utilize eco-friendly inks, providing a more sustainable approach to printing. This shift toward environmentally responsible practices appeals to conscious consumers who are increasingly seeking brands that prioritize sustainability in their production processes.

Additionally, DTF printing minimizes waste through its efficient transfer process. The method enables printers to produce designs without requiring excessive amounts of ink or materials, contributing to lower overall resource usage. The focus on sustainability not only benefits the planet but also enhances brand loyalty as consumers align themselves with businesses that share their values.

The Cost-Effectiveness of DTF Transfers in Business

One of the most compelling reasons for businesses to adopt DTF transfers is the significant cost savings associated with the process. Compared to traditional garment printing methods like Direct-to-Garment (DTG) printing, DTF technology lowers costs by allowing for bulk production and reducing overall waste. This aspect is especially beneficial for small to medium-sized enterprises, enabling them to compete effectively in the market without incurring excessive financial burdens.

Moreover, as demand for DTF printing continues to rise, the costs of necessary equipment and supplies are expected to decline, making this technology even more accessible to new entrants in the industry. This aspect of affordability allows startups to invest in high-quality printing processes while maintaining low overhead costs, resulting in better pricing for consumers and improved profit margins for businesses.

Simplifying the DTF Printing Process

The Direct-to-Film printing process is remarkably straightforward, making it an attractive option for newcomers in the textile printing industry. By utilizing a specialized printer, firms can easily apply designs to film that is later transferred onto various garments with the use of heat. This simplicity reduces the need for extensive training or knowledge of complex machinery, enabling businesses to quickly adapt to this technology and start producing quality prints almost immediately.

This ease of integration also encourages innovation among designers and businesses, as they are empowered to explore new artistic ideas and trends without the intimidation of a complicated process. With DTF, companies can launch new offerings or customize existing designs efficiently, helping them stay relevant and competitive in the fast-paced fashion market.

Navigating Environmental Concerns in DTF Printing

While DTF printing offers numerous advantages, it is crucial for businesses to address the environmental considerations associated with this technology. The traditional use of plastisol inks raises valid concerns about sustainability, compelling manufacturers to develop greener alternatives. Innovations in water-based inks are paving the way for eco-friendly options in DTF printing, allowing companies to mitigate their environmental footprint.

By prioritizing the use of sustainable inks and materials, businesses can appeal to a market that is keen on supporting brands with environmentally responsible practices. Demonstrating a commitment to sustainability not only helps to address consumer concerns but can also significantly enhance a company’s public perception, leading to increased loyalty from customers who value eco-consciousness.

The Rising Demand for DTF Transfers in the Market

As the textile printing industry evolves, the demand for DTF transfers is rapidly increasing. Businesses are recognizing that this technology provides a feasible solution for producing customizable and short-run orders, allowing them to respond swiftly to market trends. The demand for personalized products is at an all-time high, and DTF printing meets this challenge by providing a quick, high-quality solution for manufacturers and retailers alike.

Furthermore, the adaptability of DTF printing is appealing to businesses looking to diversify their product offerings. As more companies incorporate DTF technology into their operations, we can expect continued growth in the market. This trend underscores the importance of agility and responsiveness in the apparel industry, reinforcing DTF transfers as a critical component in meeting contemporary consumer expectations.

Frequently Asked Questions

What are the key advantages of DTF transfers in textile printing?

DTF transfers offer several advantages, including exceptional print quality with vibrant colors, durability against cracking and fading, versatility across various fabric types, and cost efficiency for small to medium production runs. This makes DTF an appealing choice in the evolving landscape of textile printing technology.

How does the DTF printing process work compared to other garment printing methods?

The DTF printing process involves printing designs onto a specialized film, applying adhesive powder, and heat-pressing the design onto garments. This straightforward method is simpler than many other garment printing technologies, minimizing the need for specialized equipment and making it more accessible for newcomers.

What materials can be used with DTF printing technology?

DTF printing technology is versatile and can be used on a wide range of materials, including cotton, polyester, and blends. This flexibility allows businesses to cater to diverse products and market demands, making DTF a valuable method in garment printing.

Are DTF transfers eco-friendly, and what steps are being taken toward sustainability?

While traditional DTF transfers use plastisol inks, which raise environmental concerns, manufacturers are increasingly exploring eco-friendly alternatives such as water-based inks. This shift towards sustainability reflects growing consumer preferences for environmentally conscious brands in the textile printing industry.

How does DTF printing compare to Direct-to-Garment (DTG) printing in terms of cost efficiency?

DTF printing tends to be more cost-effective than Direct-to-Garment (DTG) printing, particularly for smaller runs. DTF allows for bulk production, reducing the cost per unit, making it an attractive option for small businesses and startups aiming to control production costs.

Why is there a growing demand for DTF transfers in the printing industry?

The growing demand for DTF transfers is driven by the need for customizable, high-quality prints and the capacity for short-run production. As brands seek to meet consumer expectations for personalized products, DTF technology is increasingly recognized for its speed, quality, and versatility.

| Key Points | Description |

|---|---|

| Introduction | DTF transfers are transforming the printing industry, particularly in textile printing, offering quality, flexibility, cost savings, and durability. |

| Versatility | DTF technology allows printing on various materials like cotton and polyester, making it suitable for diverse products. |

| High Quality and Durability | DTF prints boast vibrant colors and durability, remaining intact after multiple washes, appealing to quality-conscious consumers. |

| Cost Efficiency | Cost-effective for small to medium enterprises, especially for small runs, reducing per unit costs. |

| Simplicity of the DTF Process | The process is straightforward, requiring minimal specialized equipment, making it easy for newcomers to adopt. |

| Environmental Considerations | Concerns about the use of plastisol inks have led to the exploration of eco-friendly alternatives like water-based inks. |

| Growing Demand | The market for DTF printing is expanding due to the rising demand for customizable and short-run production. |

| Recent Developments | Advancements in printing technology and materials are improving the quality and efficiency of DTF transfers. |

Summary

DTF Transfers are markedly changing the landscape of textile printing, offering a unique blend of versatility, quality, cost-effectiveness, and simplicity. As more businesses, from startups to established brands, integrate DTF technology into their operations, they are responding to the increasing consumer demand for customization and sustainability. By utilizing DTF transfers, companies can not only produce vibrant, durable prints but also do so in a way that aligns with the evolving market trends geared towards eco-friendliness and innovation. This technology is not just a passing trend but a robust solution that is set to shape the future of garment production.